|

March 13, 2005:

(2.0 hrs.) Cut the wing walk doubler skin to the correct

dimensions and then match drilled it to the top inboard skin for the

right wing. |

|

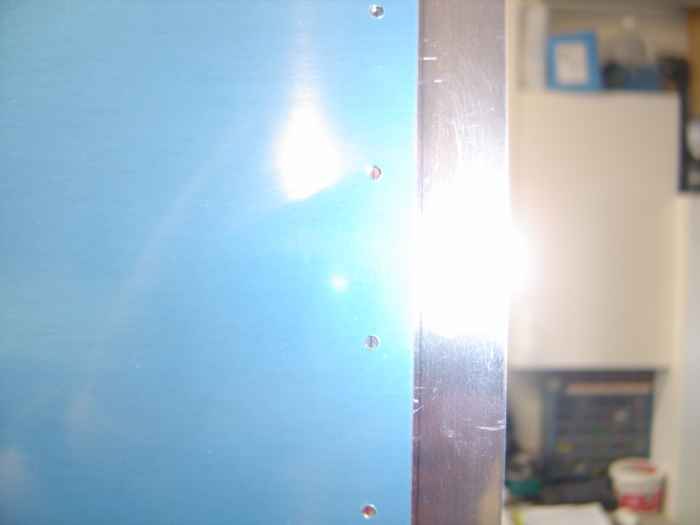

Hung the top right wing skins in place.

I noticed that I had to adjust the position of the rear spar slightly to

facilitate aligning some of the holes. After both the inboard and

outboard top skins were attached, I then checked my plumb lines for any

wing twist. I think I had about 1/8" twist from end to end.

I removed the twist by adjusting the rear spar position and clamping

every thing down tightly. When I was satisfied with the positioning of

everything, I match drilled the skin to the ribs and spars. |

|

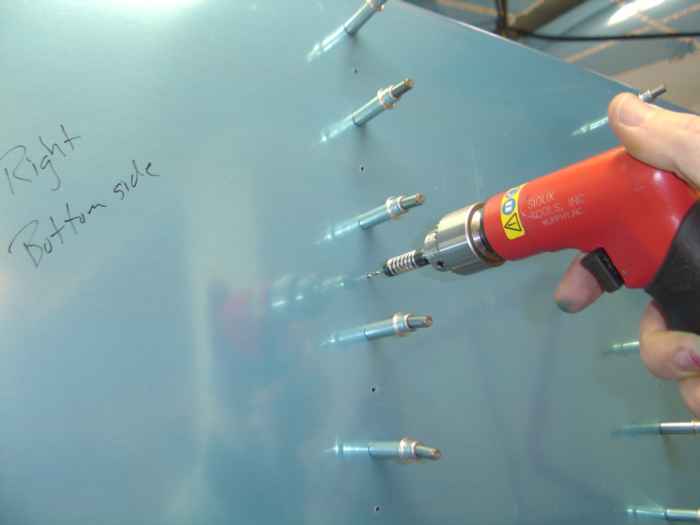

Next, I attached the bottom skins.

Where the skins overlap the inboard and outboard ribs, I had to cut a

small notch in the jig's aluminum angle hangers to allow the skin to fit

properly (sorry no pictures of that). |

|

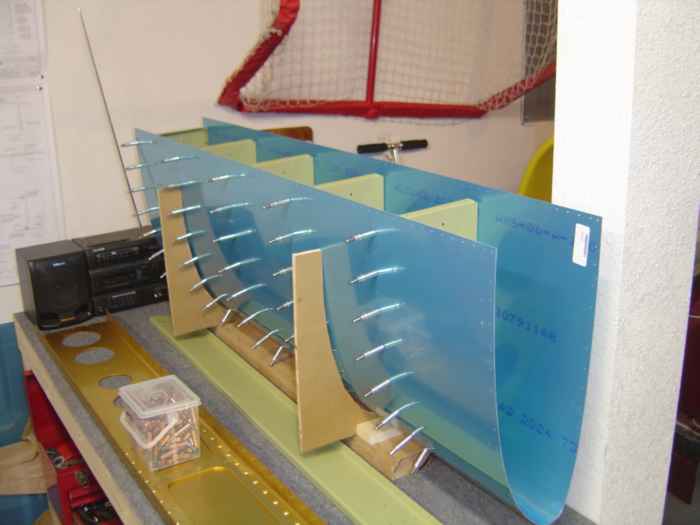

Placed the leading edge skin in its jig

and cleco'd the nose ribs in position. Notice that these ribs are

already primed. I took care of these at the same time I did the

main ribs.

The plans call out removing the interior blue film from the leading

edge prior to fitting... oops, guess I got carried away. I am

really not sure why they call this out. Any extra thickness the

film adds would be minimal. I would not expect that to effect my initial

fitting to the main wing. |

|

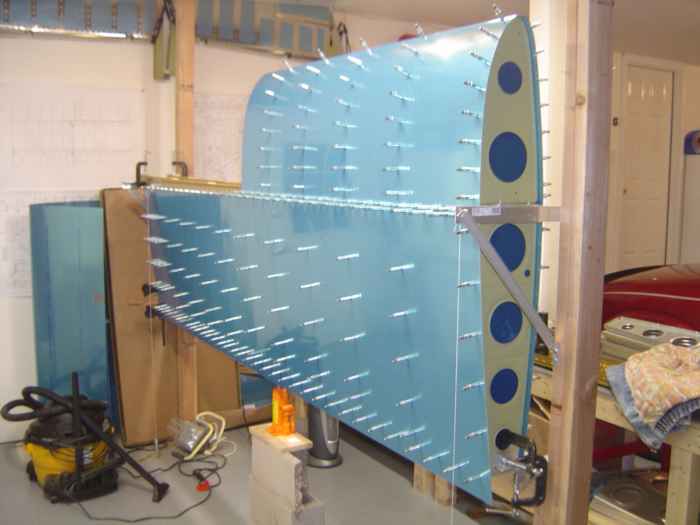

Here is the leading edge attached to the

wing. |

|

March 26, 2005:

(2.0 hrs.) Finally got back to work on the plane after having

been out traveling for a week and then home sick for a week.

I had to finish match drilling the leading edge

skins and also the bottom skins. |

|

Inserted the inboard rib of the leading

edge and match drilled the back flange through the pre-drilled holes in

the main spar. I used a 12" bit with a little flex held in it to

get these drilled out. |

|

After cleco'ing the end rib in place, I

was able to insert the leading edge joint plate (W-423) between the skin

and the end rib. The joint plate and the end rib are not

pre-drilled, so it is important that everything is perfectly aligned

measurement wise before match drilling with the skin.

I drew a line 1/2" in from the outboard end of the joint plate.

When the plate is inserted correctly, this line will appear through the

pre-drilled skin holes. I also had to measure to make sure the rib

stayed positioned correctly after having shoved the joint plate in

place. I had to move the rib around a bit after measuring its

distance from the outside edge of the joint plate all around the

assembly. |

|

With things all positioned, I drilled the

assembly using the skin holes as a guide and cleco'ing along the way. |

|

Joint plate attached. |

|

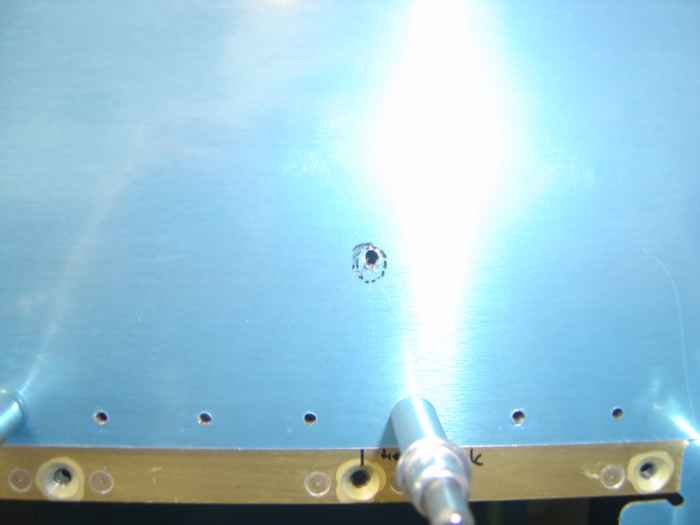

The bottom of the leading edge skin has a

pre-drilled hole marking the location of the tie-down which needs to be

enlarged. I determined this guide hole was slightly off, so I

filed the hole so that it was positioned correctly. I then used a

step-drill to enlarge the hole. |

|

|

|

|

|

|

|

|

|

|

|

|