|

November 26-27, 2005:

(4.0 hrs.) Now that the ailerons are attached, I can mount

the flaps, using the ailerons as a reference for the trailing edge

distance.

Here I have clamped a piece of aluminum angle to

the trailing edge of the aileron to give me a reference line for where

the trailing edge of the flap should be. |

|

With the flap clamped in place, I match

drill and cleco the flap hinge to the wing skin and gap seal. The

tricky part here is getting started because the wing skin, gap seal and

aileron hinge all need to be held in place and drilled. Once you

have your first hole drilled, a cleco can be used to hold it all

together making drilling the the following holes much easier. |

|

All the holes are drilled and cleco'd.

Next, all the clecos get removed, the parts get deburred, the parts get

cleco'd back into place, and the parts get riveted with the hand

squeezer. |

|

To make installation and removal of the

flap easy, I chose to remove a few sections of eyelets from the middle

of the flap hinge so that the hinge pin can be inserted in two pieces

from the middle. Here you can see the two ends of the bent hinge pins

meeting in the middle of the flap hinge. These will get safety

wired together at a later date. |

|

Here is a shot of the aileron and flap

trailing edge alignment. Its within 1/32". Certainly good

enough. |

|

With the flaps now done, there are just a

few items to tend to the wings, one of which is installation of the

pitot tube.

This picture shows the 1/4" aluminum tubing run and wiring harness to

the heated pitot tube. I used Molex connector on my wire harness

to make removal of the pitot tube easy. |

|

The pitot tube and wire harness runs go

right under the aileron bell-crank. |

|

I picked up some #6 stainless screws at

Home Depot, drilled/tapped the pitot mount and tube, and installed the

pitot tube. Looks pretty good. |

|

October 5 - 26, 2008:

(12.0 hrs.)

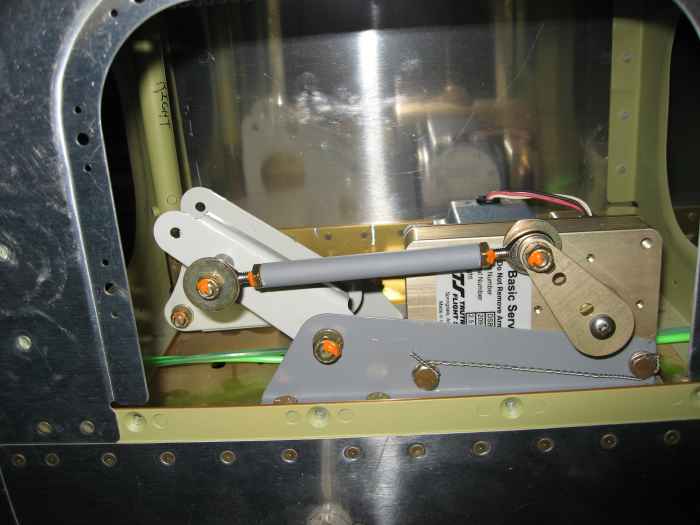

Installed the roll server for my TruTrak autopilot in the right wing.

Here it is all installed. Bolts torqued and safety wired. |

|

One thing I never got around to doing

after I initially fitted the wings, was trimming the flaps where they

meet the fuselage. I had marked the trim line (shown in the

picture), but never did the trimming. |

|

After some work with the felt sander,

file, and ScotchBrite wheel.. the flaps are trimmed. |

|

When I originally fit the wings to the

fuselage, I never got a chance to match drill the wing root fairings

because I did not have the wing root fairings! Van's for some

annoying reason does not provide those in the wing kit, but the finish

kit. Well, I decided that since the majority of holes in the fairing

and wing skin are pre-punched, that match drilling things while the

wings are mated to the fuselage is not that critical. So, I went

ahead and did it with the wings off and then installed the gizillion

nut-plates. I don't suspect this will be a problem later.

Worst case is that I need to trim the fairing down a bit during the wing

mating process. |

|

Ah, the last thing I had to do was install

all the nut-plates in the wing access points. Did I mention how

sick I am of installing nut-plates? |