|

April 15, 2005:

(6.0 hrs.) Today was a busy day. With my

father-in-law Max around to help out, a lot was accomplished.

With the leading edge and skins removed, I

countersunk the holes in the main spar to accept the dimples in the

skins.

|

|

After countersinking, I wanted to prime

all the raw exposed aluminum. Since there were so many holes, I

decided to just mask the spar and ribs off and spray the area. |

|

Here is the spar with the countersunk

holes for the skin primed. This priming method was much more

effective and easy than using a q-tip and dabbing each hole.

That guy in the background is Max running a debur bit in all the

holes of the top in-board skin. |

|

While I was working on other portions of

the wing, Max stripped the blue plastic from the two top skins and

deburred all the holes. It is great to have someone around willing

to help with these simple but tedious tasks. |

|

After deburring the inside and outside of

the ribs, the hand squeezer was used to dimple the holes. |

|

Did not remember to take any photos of the

process, but Max and I riveted the leading edge together. Here it

is sitting on the main spar. |

|

April 16, 2005:

(1.0 hrs.) With the skins deburred, it was time to start

dimpling.

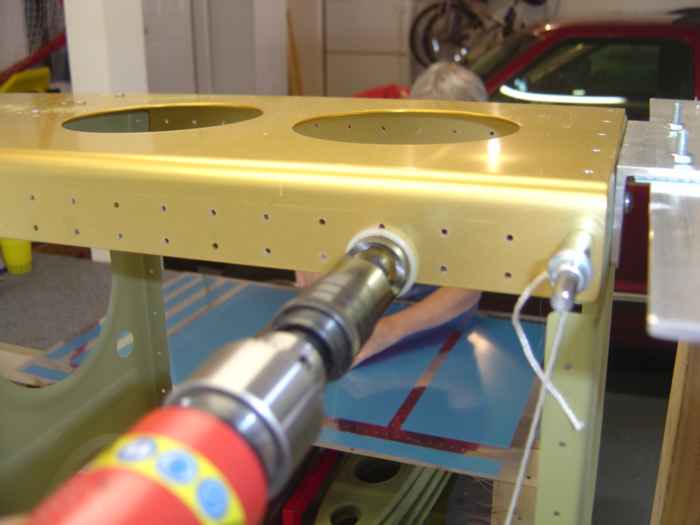

Here the c-frame dimpler is setup to get the

center most holes in the top skins. |

|

I used my hand squeezer to dimple all the

holes around the perimeter of the skins.

The top skins are now dimpled and ready to go. |