|

June 10, 2005:

(4.0 hrs.) My goal today is to get the top skins on and the

wing out of the jig. First things first... I needed to create the

scarf joint where the top skins overlap and butt up against the tank

skin. I used an orbital sander to do this. I don't have any

pictures of the process, just the end results shown below.

Here I am working the 3x rivet gun with flush set.

Oops, I forgot my eye protection. |

|

Here is Max bucking rivets for me.

With two people, we make quick work of all the rivets in the wing. |

|

For the inboard rib and bottom edge rivets

used my hand squeezer on the rivets. |

|

Here is a picture of the scarf joint.

The objective is to get the leading edge of the skins to sit as flush as

possible with the tank skin... You don't need to worry about the seam

cutting across the width of the wing. I think mine turned out

pretty nice... I made sure to prime all the sanded areas, hence

the green primer color. |

|

Here is the right wing with the top skins

installed. Nice! |

|

After building the wing cradle (about an

hour), the wing was removed from the jig and set into the cradle.

Another milestone reached. Next I will put together the left wing

skeleton and get it into the jig. |

|

June 11, 2005:

(1.0 hrs.) With the right wing out of the jig, it was time

to start assembly on the left wing. I had a little bit of

deburring to do on rib attach points to the spar. After that

was complete, all the ribs were clecoed to the main spar for riveting.

Boy am I glad that I spent all the time up front to flange, flute, debur,

prep, and prime all the ribs. It is really nice to be able to just

take the parts and start assembly. With Max

working the bucking bar, we quickly riveted the first 6 inboard ribs and

then had to quit for the day. |

|

June 13, 2005:

(2.0 hrs.) I lost my bucking partner so I had to finish the

riveting on the main spar myself. As long as I keep the pressure

up to about 60 PSI on my 3x gun, these AN4 rivets are a breeze.

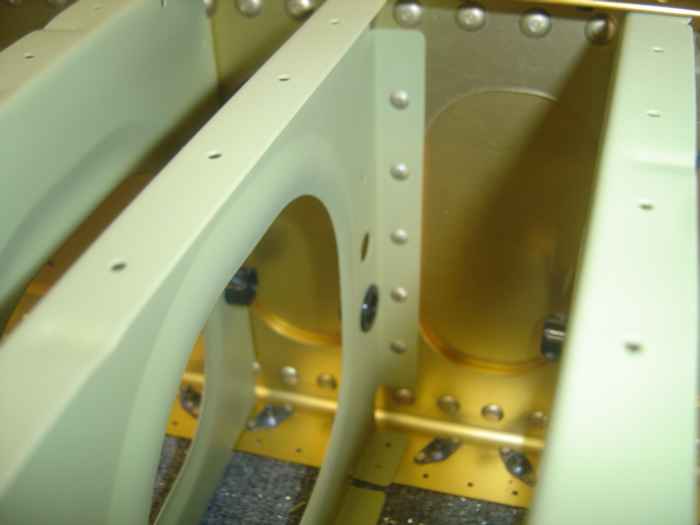

Here is a shot of the rivets on one of the inboard

ribs. |

|

When all the rivets on the main spar were

set, I attached the rear spar using my hand squeezer to set the rivets.

Next it was time to get the skeleton mounted in the jig. Having

done this already once, it was much faster the second time. Since

this is all repeat of what was done on the right wing, I will not go

into the details.... Check for level, plumb, sag, twist and then clamp.

|