|

September 30, 2005:

(3.0 hrs.) I was planning on not closing up the wings until

I had made all my electrical runs, but I really wanted to get my flaps

mounted which requires the bottom skins be attached. When I

learned my father-in-law Max would be coming to town for a while, I

thought I would take advantage of having a helper around and get the

wings closed up. It should not be a problem to make the electrical

runs after the fact.

First things first. The inboard skin gets

installed. Here the skin is peeled back a bit and I am reaching up

to buck the rivets on the trailing edge between the wing walk ribs.

This is a real pain because there is not much room to get your hand up

in between these ribs. |

|

I convinced my sister-in-law, Kelley, to

burn-and-peel the blue plastic from the rivet lines on the left wing

bottom skins while Max and I were attaching the bottom skins to the

right wing. |

|

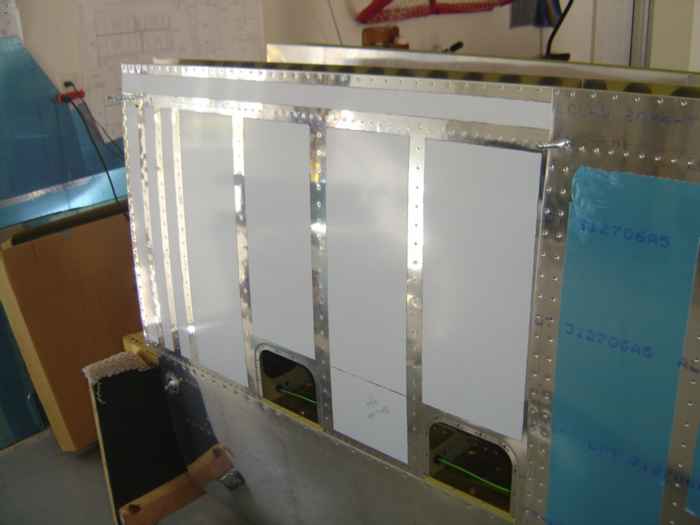

Right wing bottom inboard skin is

attached. We also managed to rivet the first bay for the outboard

skin before calling it quits for the afternoon. |

|

October 1, 2005:

(2.0 hrs.) Worked on finishing up the outboard bottom skin

of the right wing. Here I have peeled back the skin to reach in

and buck the ribs of the 3rd bay from the outboard end. I pretty

much followed the recommended rivet pattern from Van's for attaching

these skins. |

|

One more shot of working from behind the

peeled back skins. |

|

Right wing closed! This thing is

starting to look like it might fly. |

|

|

|

|

October 2, 2005:

(3.0 hrs.) Max is leaving town tomorrow, so I wanted to try

to get as much done on closing the left wing as possible. Who

knows when I will next have a helper around again.

The day started out with deburring and dimpling the

left inboard and outboard skins.

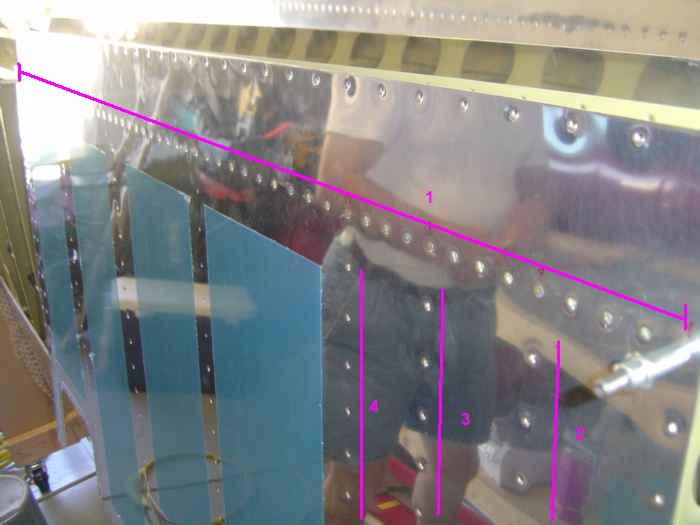

Here the inboard skin is being attached. I

found that riveting the entire line of rivets along the rear spar to be

the best first step. Next, starting at the inboard end, I would

rivet down (trailing edge to leading edge in my case) each rib by

reaching in from the root end with the bucking bar. In between

doing each rib, I would rivet along the bottom (leading edge spar)

towards the outboard wing tip. The last wing walk rib would get

bucked by reaching in from the first wing access opening and then

through the rib lightening holes of the adjacent rib. This rib

(labeled #4) is one of the more difficult ribs to reach. After

that, all ribs are easy to access via the wing access openings. |

|

In my haste to dimple the skins I missed a

few rivet holes and did not realize this until the skin was already

riveted to the skeleton. I used my close quarters dimple set to

apply these dimple with the skins in place. This dimple die set

uses a pop rivet gun to set the dimple. |

|

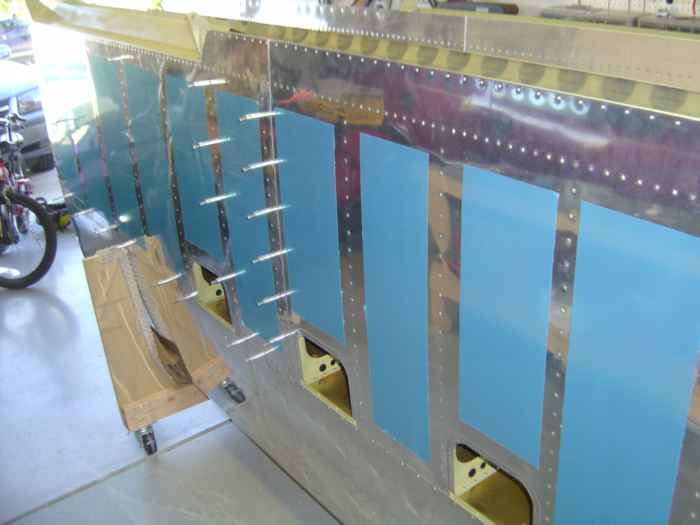

Managed to get the left wing inboard

bottom skin completed and part of the outboard skin. |