|

February 6, 2005:

(3.0 hrs.) After countersinking all the holes in the spars

yesterday, I wanted to get that fresh aluminum exposed by the cuts

covered up. I used a q-Tip to apply primer to the countersunk

holes.

|

|

Once the primer was dry I cleco'd in one

side of the nut-plates to hold them in place while flush riveted the

other side of the nut-plate with my hand squeezer. Next I removed

the cleco's and riveted the second side of the nut-plates |

|

Since I had installed the attach point nut

plates for one side of the wing access covers (there are six of them), I

decided to go ahead and drill, debur, and dimple them at this point.

The access plates take a #8 screw and dimple on all sides except the one

that attaches to the main spar. A #6 screw and dimple are used at

the spar attach point. |

|

Here are the completed wing access plates. |

|

The last part of the spar assembly is

attaching the wing tie-down points. Four spacers need to be

fabricated that wedge behind the tie-down assembly and the wing spar.

Here is the aluminum stock used to make the spaces marked for

drilling and cutting according to the plans. |

|

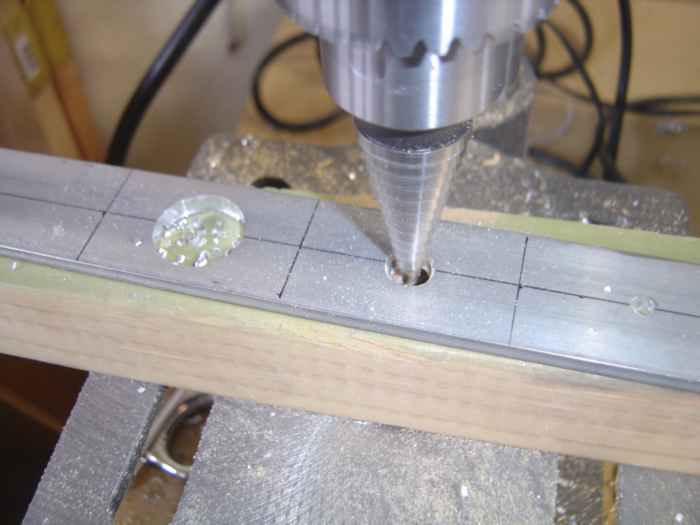

Each spacer has a lightening hold drilled

in it for weight reduction. Using my drill press i drilled a pilot

hole for each spacer. |

|

Next, I used my step drill to enlarge the

holes to 7/8". The plans call for 1" lightening holes, but my step

drill only went up to 7/8". Not a big deal as the only purpose of

this hole is to reduce the weight of the assembly. |

|

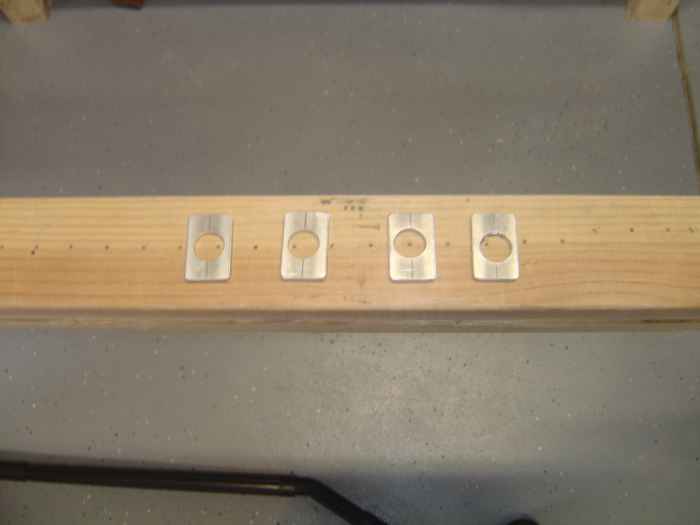

Here are the spacers drilled and cut to

length. Tomorrow I will try to find time to match drill the

tie-down point and spacers to the main spar. |

|

February 11, 2005:

(2.0 hrs.) Decided that I wanted to make my tank countersinks a

little deeper so I ran my micro-stop countersink cutter on all the

center holes again. Since I had already set all the nut-plates I

could not use the same jig I used earlier for countersinking these

holes. Instead, I just countersunk with the nut-plates in place.

This worked remarkably well, the pilot of the countersink would align

with the bottom of the nut-plate resulting in a perfectly centered hole. |

|

Here is a picture of the holes countersunk

a second time. You can see some shavings in the joint on the

spar... shame on me, I forgot to cover it with tape prior to

countersinking. I got them all out with the Shop Vac. Next

time I have the paint out I will need to touch up these countersunk

holes. |

|

Decided to try and get started on the rear

spars. The inboard stiffener plats need to be trimmed. The

light makes it kind of hard to see in the picture, but if you look

carefully you can see where I have marked the stiffeners for cutting

(bottom right corner). |

|

I cleco'd all four stiffener plates

together and cut them in one pass on the bandsaw. |

|

Next, I radiused all the corners and then

deburred all the edges of the stiffeners. Here I have clamped one

of the stiffeners in place and used my file to remove all the milling

marks from the edges. |