|

September 23-24,

2006:

(4.0 hrs.)

I have been away from the project for about two weeks because of work

related travel. It seems like there are a million little things

that need to be worked on. I decided to work on the seat belt

crotch strap. This is an add-on component to the Vans kits that I

think is well worth it. Adding the 5th point to your seat belt

system can add to the survivor-ability of a crash, especially if it is a

flip over.

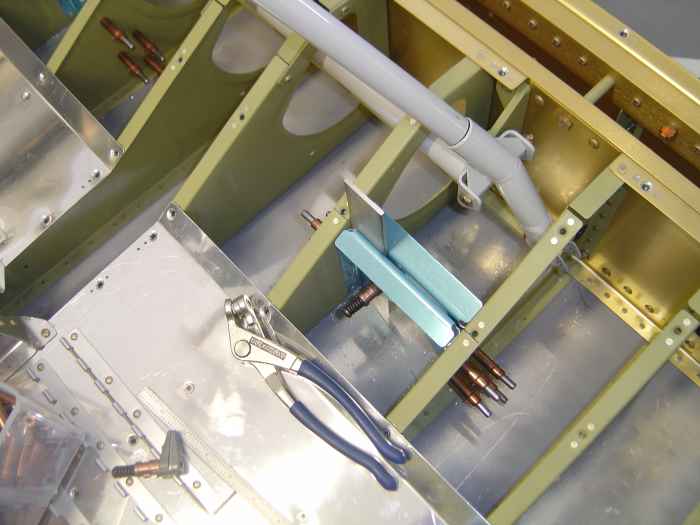

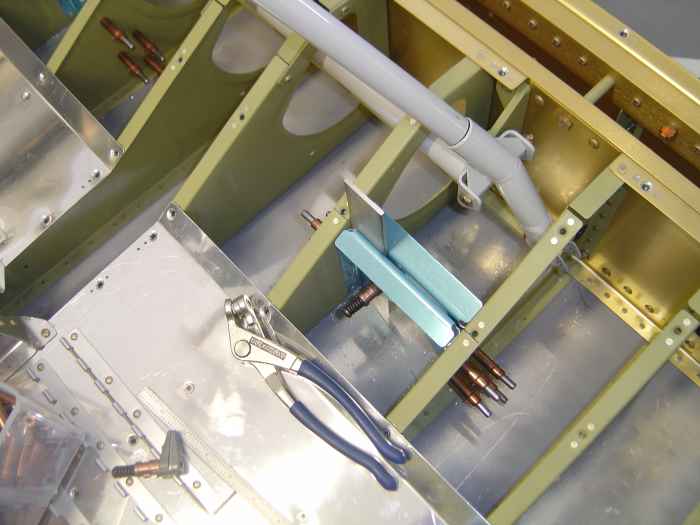

Installation amounts to installing these two pre-fabricated plates

between the seat bottom ribs on both the left and right side. The

plates need to be 1/8" apart to allow the seat belt end to insert

between the plates and get fastened down with a bolt. I used a

scrap piece of aluminum as a 1/8" spacer while I clamped and drilled the

parts to the seat bottom ribs. I had to make use of my right angle

drill attachment to match drill the holes in the crotch strap plates to

the seat ribs. I then removed the parts and deburred the holes and

edges. These will get primed during my next painting session, then

I can rivet them into place. |

|

I finally received the back-ordered side

skin for the AP fuel pump cover. Now I could finish the cover

assembly. I cleco'd all the parts together in the cabin and match

drilled the holes. The right angle drill attachment had to be used

to drill the holes through the floor stiffeners into the center tunnel

cover.

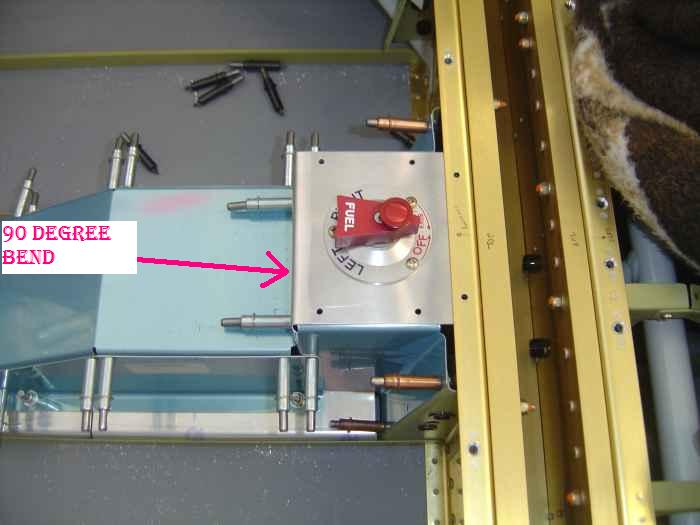

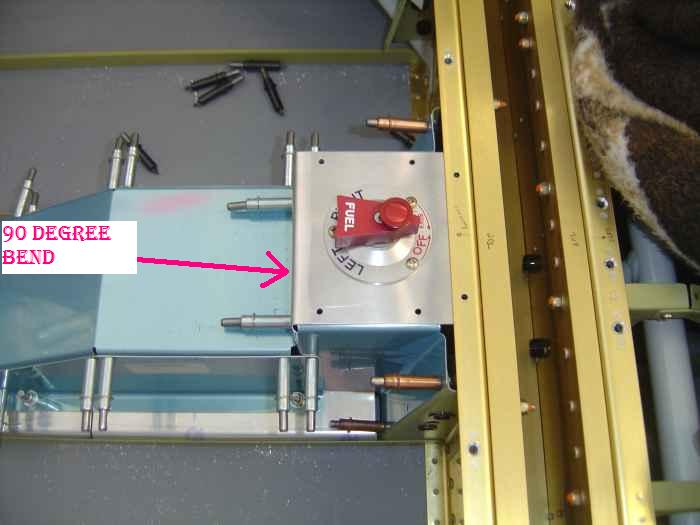

The arrow in the picture is pointing to the area on the fuel valve

cover plate that is supposed to be used to mount the manual elevator

trim. Since I have installed electric trim, this section of the

cover plate can be removed. |

|

Since I was not going to be using the

stock fuel valve, what worked out nicely on the fuel valve cover plate,

was to bend the manual trim mount area from its 30 degrees position to

90 degrees and then cut the section off leaving a 1/2" flange. The

cover plate was flipped upside down and mounted to the AP fuel pump

cover. The small bend and flange on the cover plate serves to

close any gap that would have existed if the manual trim area were just

completely removed. I chose to install an Andair FS 20x7T over

the stock fuel valve. The valve has positive locks while in the

left and right position. This will prevent any accidental bumps

switching the fuel supply off. Since I am planning on installing a

center console that attaches to the panel, I will need to get an

extension for this valve so it can be operated from the center console. |

|

Next, all the forward covers were removed.

The edges and holes were deburred. Rivet holes were dimpled and

the parts riveted. I had to use the pneumatic rivet gun on some of

the rivets. Nut-plates were also installed.

My daughter Katy was having fun with the cleco's while I worked at

the bench. |

|

September

29 - October 1, 2006:

(4.5 hrs.)

Worked on several miscellaneous items this weekend.

Prepped and primed the crotch strap parts, the AP fuel pump base, and

one of the aft top skin stiffeners. |

|

I also painted the brake pedal with

JetFlex water soluble paint. This is a special aircraft interior

paint avaialble from Sherwin-Williams. It is hard to tell from the

picture, but this is a grey/beige color. Should match nicely with

the beige leather seats I plan to install. |

|

Riveted the crotch strap attachment points

into place. These took simple blind rivets. |

|

Mounted the AP fuel pump and filter to the

base. I also began to run the numerous tubes that this system

requires. This was really my first take at tube bending.

Needless to say, I made a lot of mistakes an need to order some more

tubing. |

|

Installed the F-704 side cover plates.

This amounted to match drilling all the holes, deburring the holes,

deburring the edges, and blind riveting them into place. With

these in place, I am getting fairly close to the point of painting the

interior. |

|

Started fabrication and installation of

the aileron trim control. Here I am fitting and drilling the

support plate between the center seat ribs. |

|

The support plate is then match drilled

and fitted with nut-plates. I primed this part using the

rattle-can primer. |