|

November

17-19, 2006:

(10.0 hrs.) Decided I was going to finish all

the plumbing in the forward fuselage. I had been putting off

finishing up the plumbing on the Airflow Performance fuel pump because I

had still not found a tool that would make 180 degree bends in 3/8"

tubing. My friend Dan let me borrow a tubing bender that he used

on his Lancair project that just so happened to bend tubing 180 degrees.

Now I could finish the fuel pump! |

|

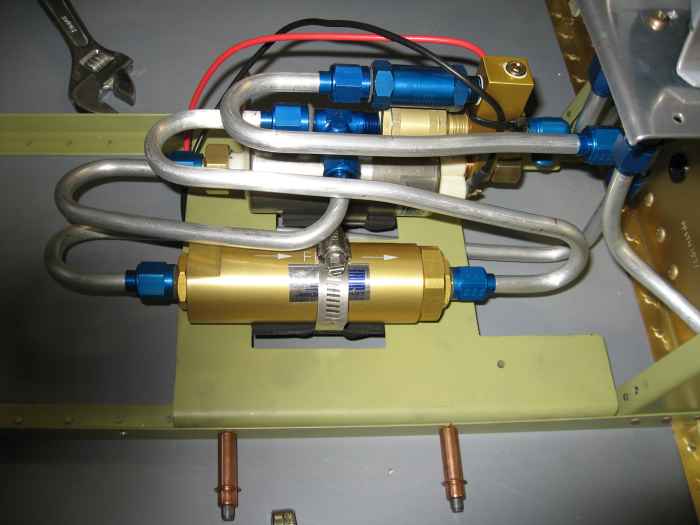

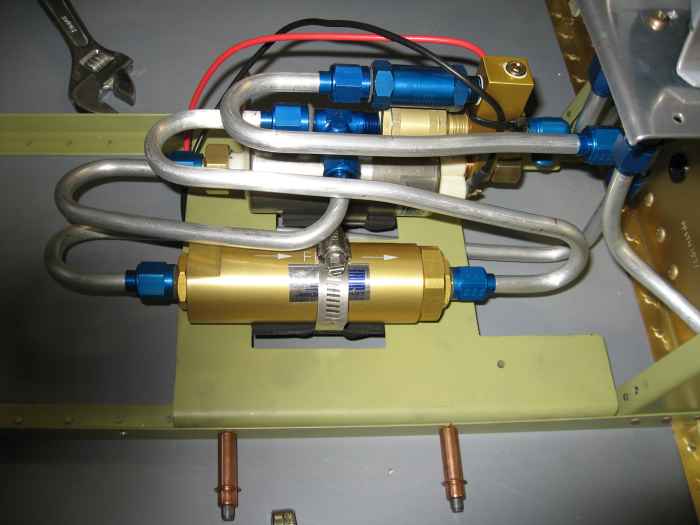

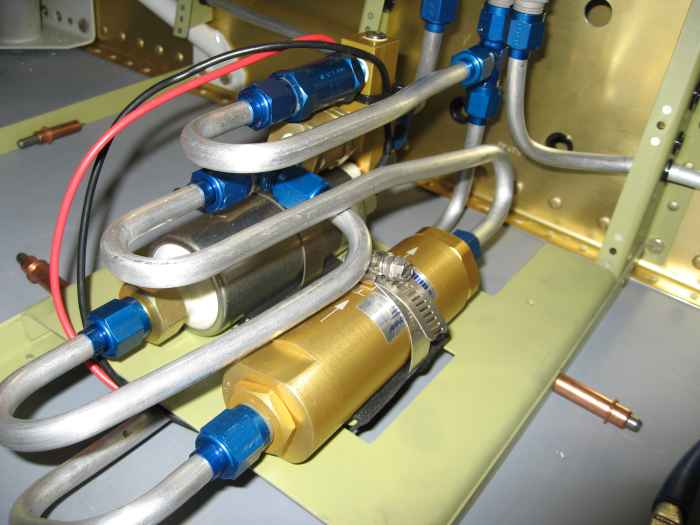

Here is the fuel pump installed with all

its lines plumbed except the engine supply line. I am going to

hold off on that line until I am sure where I will be running it through

the firewall. |

|

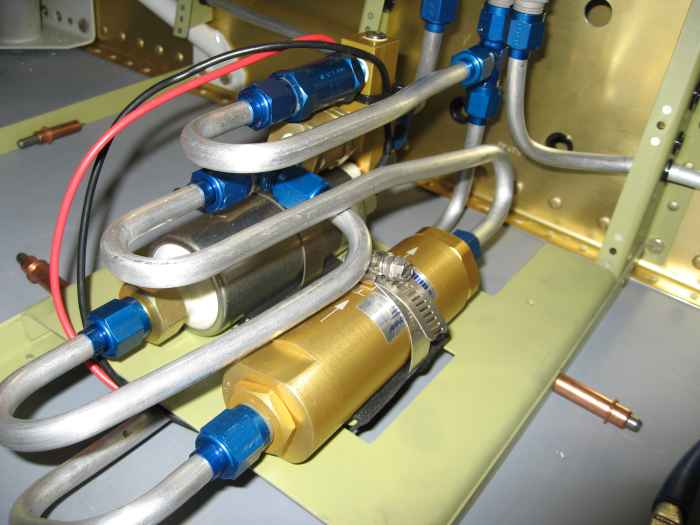

I like how these lines turned out. I

took another picture for prosperity. |

|

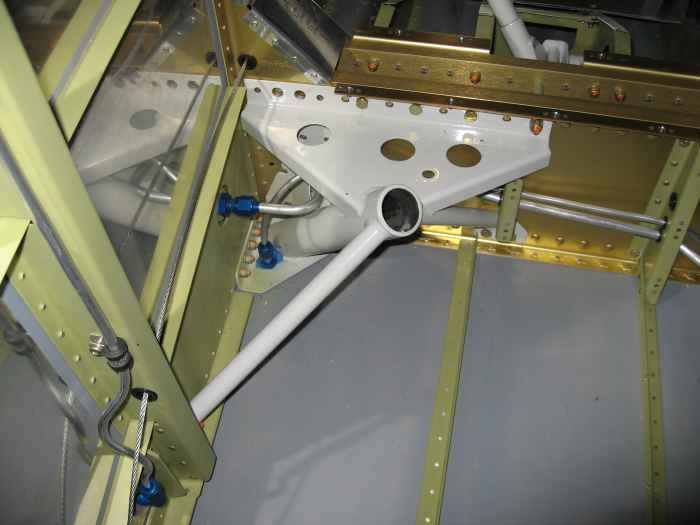

Now onto the brake lines. These use

the 1/4' tubing which is very easy to bend by hand. Here you can

see where the brake lines attach the firewall. |

|

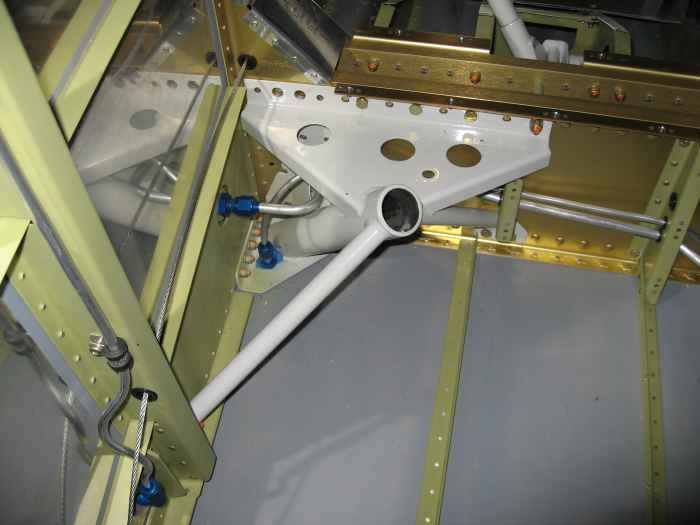

Here the brake lines run between the floor

stiffeners up to the center section. I am temporarily holding the

lines in place with duct tape. I plan to install sound proofing

under the carpet which will sandwich these lines and hold them in place. |

|

And here you can see the brake line

snaking behind the right gear leg weld-mount and connecting to the AN

bulkhead fitting on the floor. |

|

Next I moved onto some miscellaneous

items. I decided it was probably time to rivet the firewall recess

into place. The pneumatic gun and bucking bar made quick work of

these rivets. |

|

I also had to rivet these skin stiffeners

under the curvature of the top skin (just behind the canopy). |

|

I used some RTV to attach some screens to

the fuel vent line fuselage exits. This helps prevent bugs from

climbing into the vent line an clogging it. For a screen I used

the screen material that is found in faucet tips. You can pick it

up in the plumbing section of Home Depot. |

|

Next I pulled everything out of the cabin.

Floor panels, side panels, rudder pedals, vent lines, center console,

seat backs, seat bottoms, etc. These needed to be removed to get

ready for painting.

I used a medium Scotchbrite pad to clean all surfaces. That was

followed by a good vacuuming and wiping everything down with Acetone.

Here I have masked portions of the outside skins. |

|

I did not remove the stick assembly, so

that had to be masked. |

|

Most of the interior components got a

single coat of paint on the visible side. A lot of this will not

be visible after I install my interior, but I was not sure what would

and would not be seen, so everything got painted. |

|

Of course the fuselage interior was also

painted |

|

The next day, I began re-installing all

the cabin components. Some items, like the Airflow Performance

fuel pump cover will only be cleco'd into place. These will need

to come off and on several time while I work on wiring. |

|

Here is the mid-section of the cabin.

Again, some covers are just cleco'd into place for convenience. |

|

Finally, the baggage compartment. |

|

One last shot of the painted interior

looking from the firewall aft. The paint job turned out pretty

good. There are a few areas of slight orange pealing, but

considering most of this will be covered by upholstered panels, seats

and carpeting, it is definitely good enough. After this painting

experience, I think I have definitely made my mind up to have the

exterior professionally painted. |