|

September 1 - 4,

2006:

(18.0 hrs.)

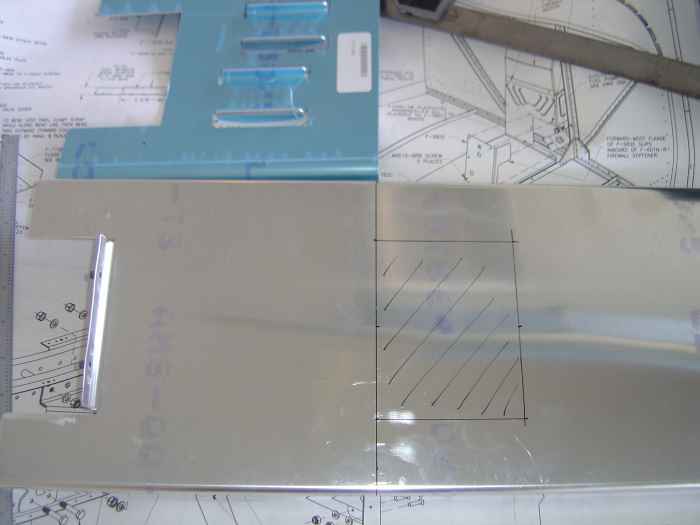

Worked on some of the forward covers in the cockpit. There are

a couple that cover the fuel lines that run along the front of the

center spar. These just need the edges deburred.

I also test fit for the forward tunnel cover and heat baffle.

The instructions indicate not to push it too far down between the center

floor stiffeners or the flanges will bend inwards and the fit will not

be ideal. I placed some wood down between the stiffeners to get

the center cover to sit at jut the right height. I am going to

wait to drill the holes for the nut-plates until I determine if I am

going to go with a center console. I am still mulling that one

over. |

|

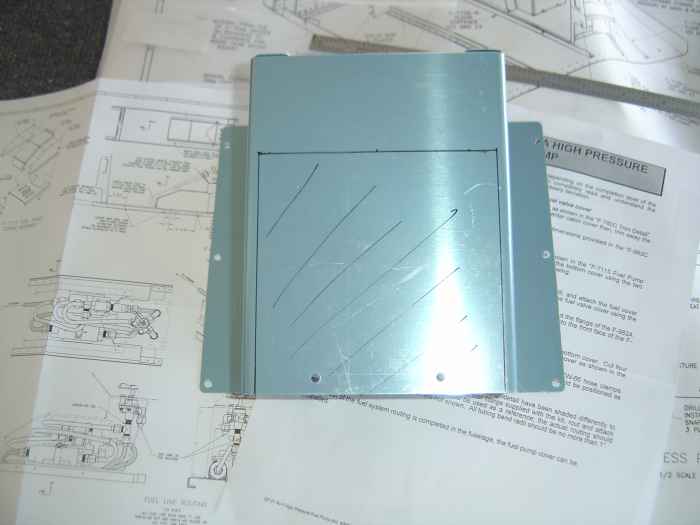

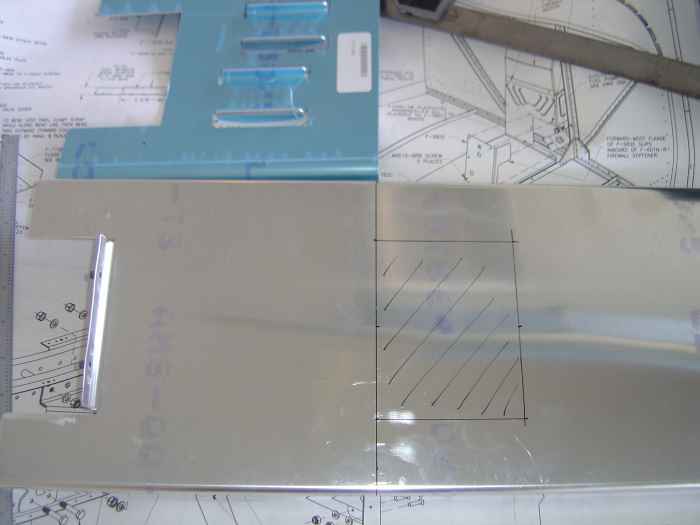

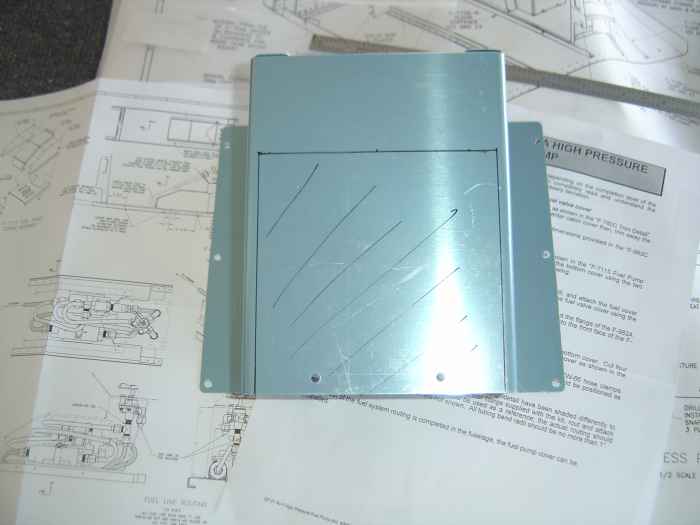

Since I will be going with a fuel injected

engine, I will be installing the Airflow Performance (AFP) auxiliary

fuel pump system. The kit arrived today from Vans, but had one of

the cover side walls on back-order. Not much I can do assembling

this thing until I get the back-ordered item. The standard center

tunnel needs to be modified when using the AFP. The rear portion

of the tunnel needs to be trimmed off to accommodate the AFP mount plate

(pictured on top). |

|

The standard fuel valve box also needs to

be modified. Here you can see the area I marked on the front of

the plate to be trimmed away.

That is about all I can do on the forward tunnel and covers until I

get the rest of my parts. |

|

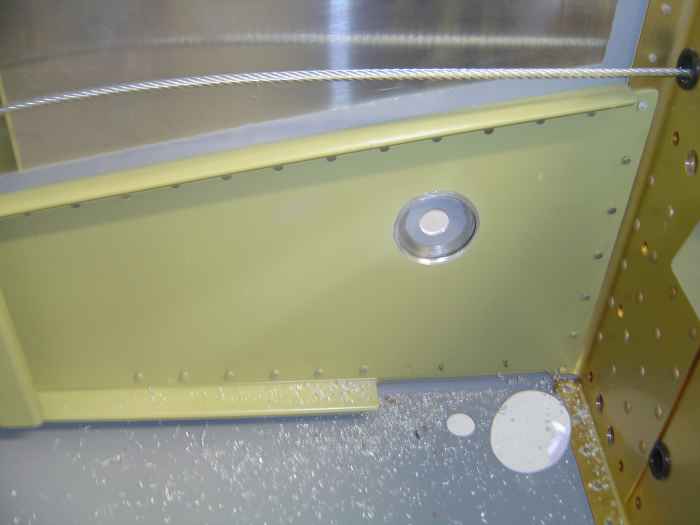

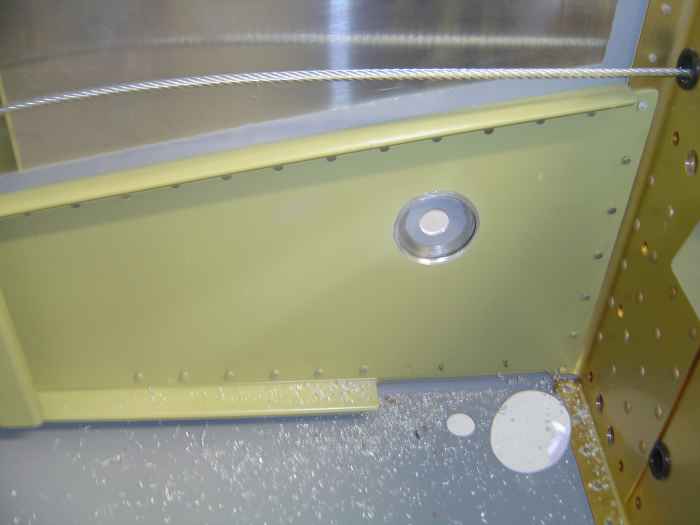

I decided that I was not going to go with

the standard rubber grommet for where the fuel line enters the fuselage.

It just seems like it will be a whole lot easier to bend and fit the

fuel supply lines if I put an AN bulkhead fitting in this location.

However, because the side skin and web stiffener are spaced about 1/8"

apart, the torque produced by the nut on a bulkhead fitting would tend

to bend the side skin in slightly. I did not like this, and

decided to cut a larger hole in just the web stiffener to allow the AN

bulkhead fitting nut and washer to lie against the side skin. I

drilled these holes very carefully with a hole saw and make-shift drill

stop. |

|

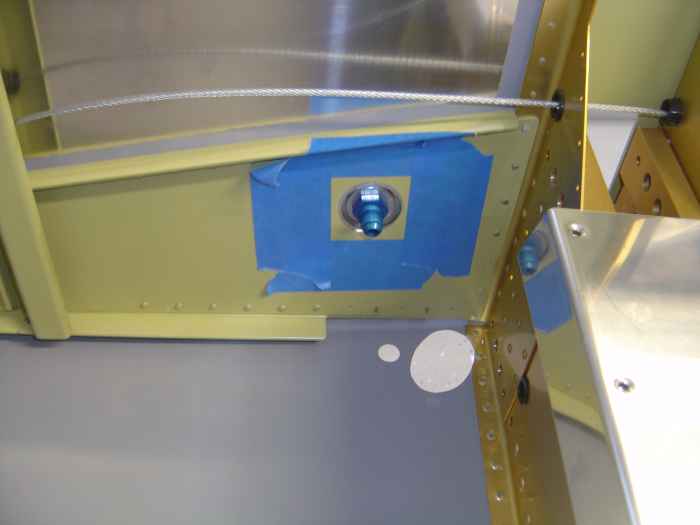

Here is right side with the AN bulkhead

fitting temporarily installed. This will come back out so I can

prime this area (hence the painters masking tape). |

|

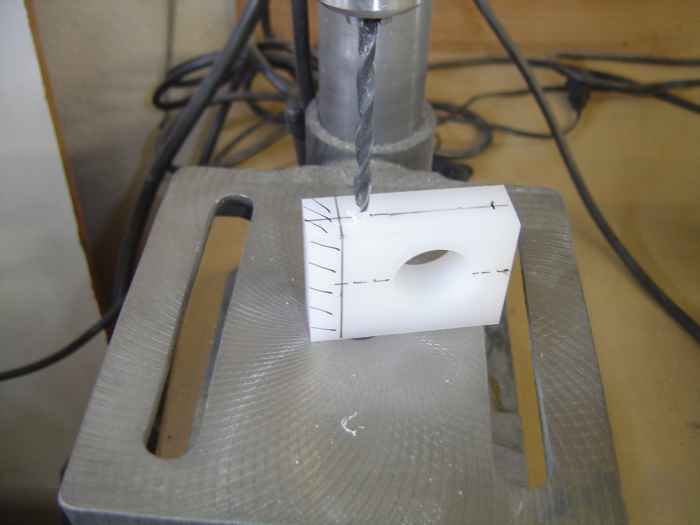

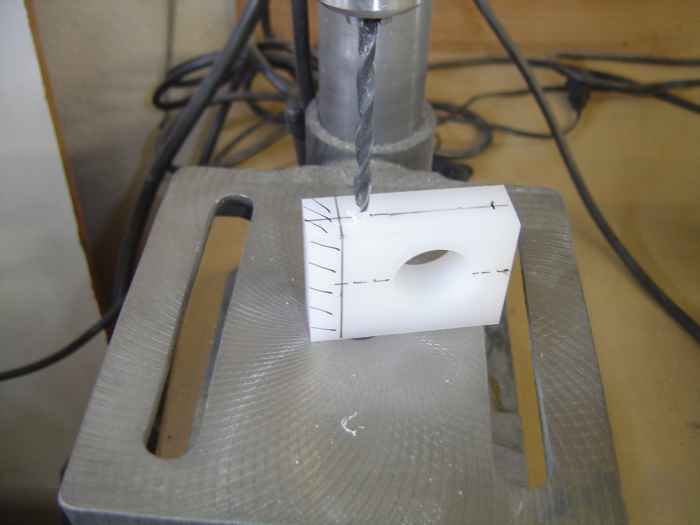

Now on to the flaps. The center

bushing block was drilled for its AN3 attachment bolts. The block

also need to be trimmed to length (note the marked area).

For some reason this block came a bit too long. It must be one of

those parts that is used on another RV model, and the extra length is

required. Once the length was trimmed, the block was cut in half |

|

The very end of the flap actuator rod has

a threaded fitting than can come loose over time. This needs to be

drilled to accept safety wire. Here I am drilling the safety wire hole

thought the side wall and out the rod end. I think I was using a

#57 drill bit. |

|

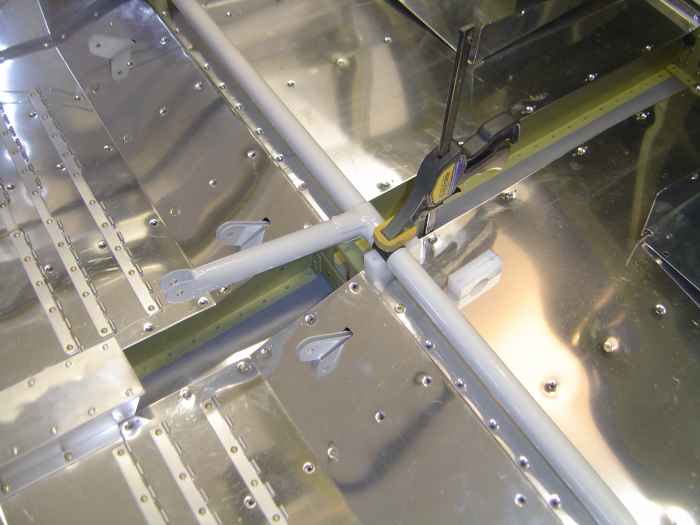

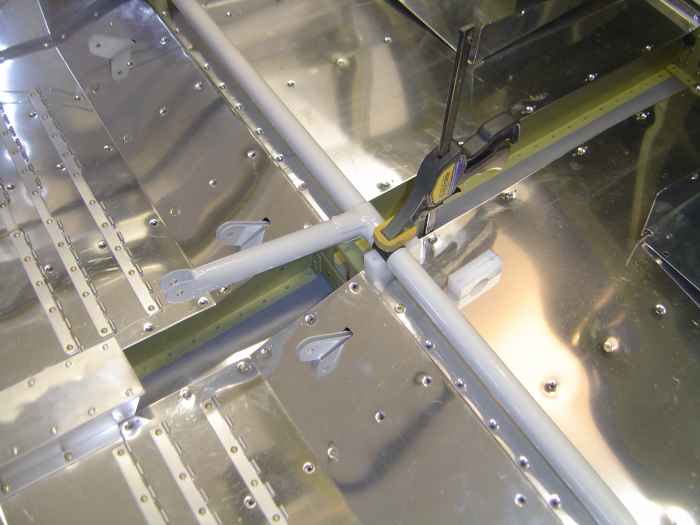

Fitting the flap weldmount in the cabin.

With the side bushing blocks bolted into place, I clamped and drilled

the center bushing block to the baggage floor skins and rib. This

all had to come back out (including the baggage floor skin), so I could

drill and install the nut-plates on the baggage floor rib that will hold

the center bushing block in place. |

|

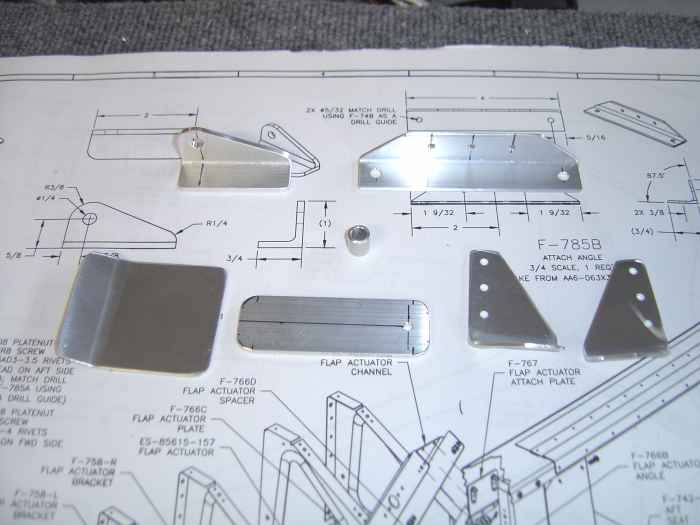

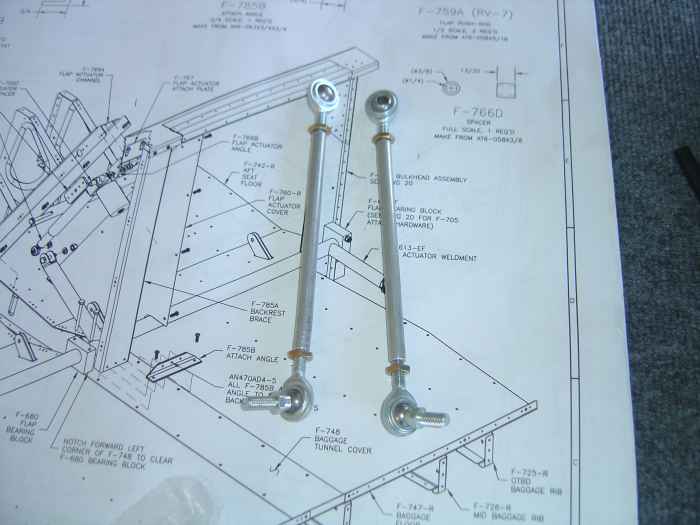

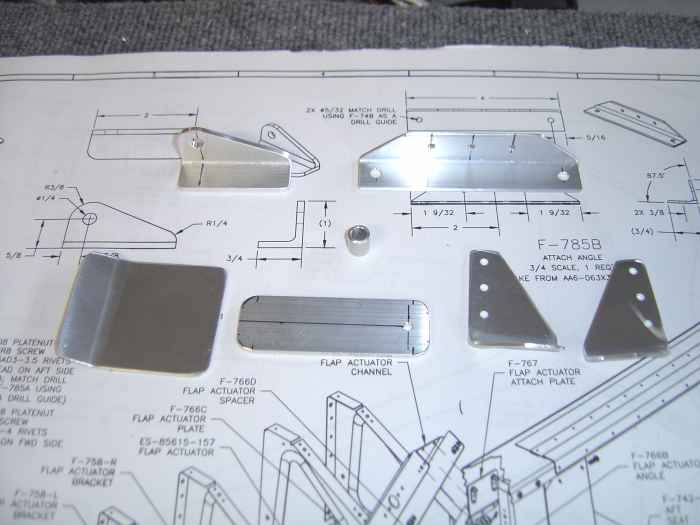

Fabricated all these parts that will be

required to complete the flap actuator install. |

|

I deburred the forward channel edges,

riveted on the nut-plates, riveted the lower supports, and riveted the

upper channel support.

I also deburred the edges of the rear channel, and riveted on its

bottom support. |

|

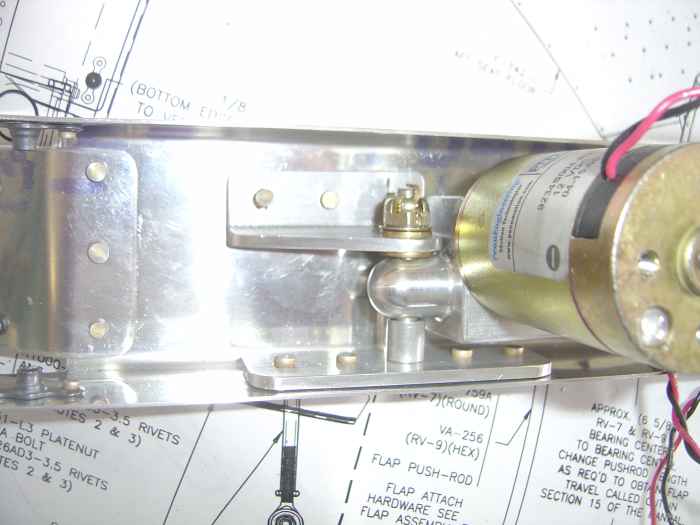

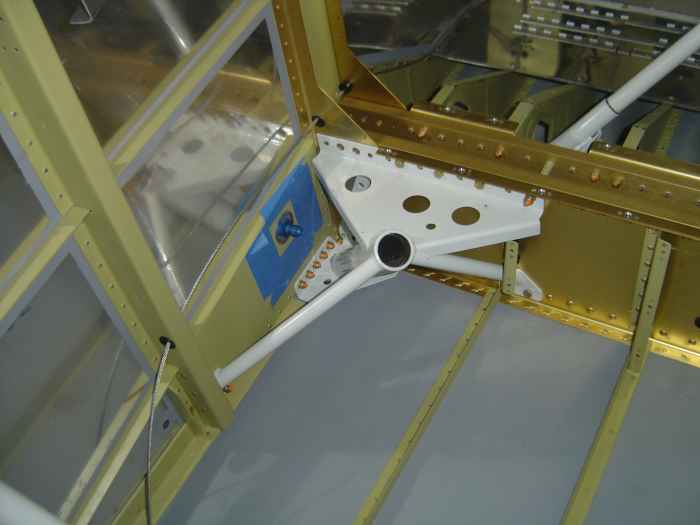

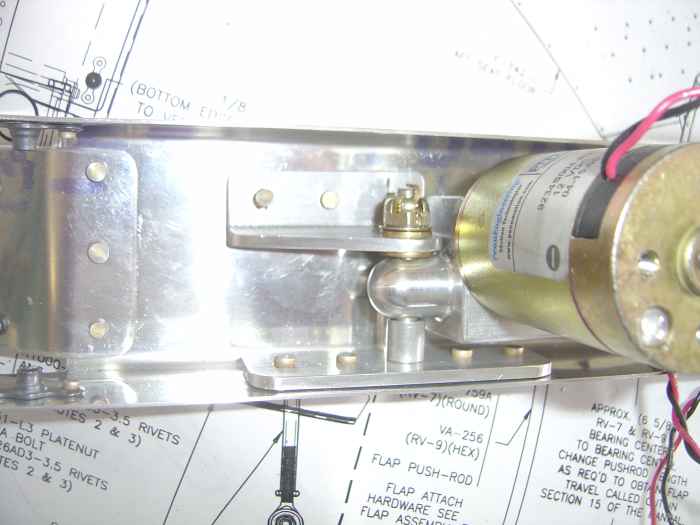

Here I have installed the forward and rear

channels. With the lower support of the front channel

screwed to the seat pans, the top support gets clamped and match drilled

to the F-705. Similarly, the rear channel gets screwed to the

baggage compartment floor and the top gets clamped and match drilled to

the back of the F-705.

The flap actuator mechanism is temporarily bolted into the front

channel with the attachment angle fabricated earlier. Interesting

enough, the AN bolt that came with the flap assembly was too long

(something like a 20). The plans called for a 16. Luckily I

happened to have one. There was no way the longer bolt would have

worked.

Anyway, with the flap actuator at its mid point extension, the angle

bracket was clamped in place (pictured), and things were match drilled

through the forward channel. |

|

Here is the flap actuator assembly after

everything has been deburred and riveted into place. |

|

Next, the side panels were screwed to the

front channel, and they the holes in the rear channel were match

drilled. The rear channel was then removed and fitted with

nut-plates. |

|

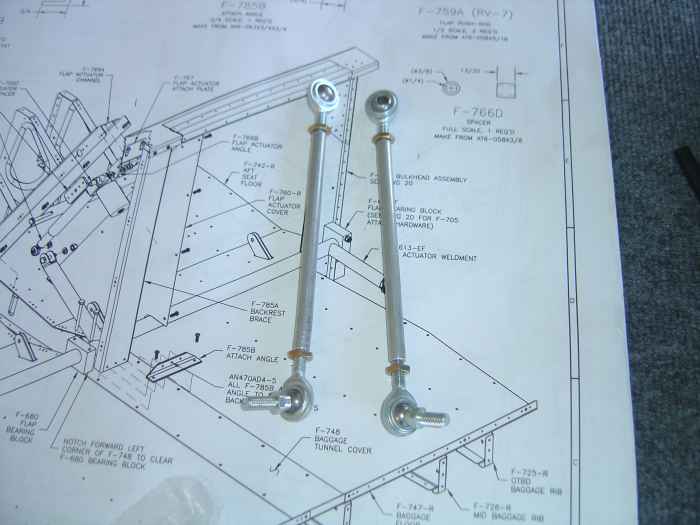

Fabricated the flap rods. This

entailed cutting the aluminum tubing to length and tapping the ends with

a 1/4" x 28 tap. |

|

Remember the goof I discovered last

weekend?... The outer forward floor stiffeners were installed backwards?

Well, I drilled out all those rivets and put the stiffeners in the

correct direction. Max was in town and shot the rivets from

underneath while I reached in bucked the tails. |

|

On to the landing gear weld mounts.

First, the inside of the gear tubes needed to be cleaned of any burs

and paint. I used some emery cloth to make things nice and smooth. |

|

Next, the gear leg is slide into the gear

weld mount and this hole at the top of the mount is match drilled with

the gear leg to 5/16". |

|

I then proceeded to install the landing

gear mounts. What I thought would be a simple task, turned into

several hours of work. I don't have any pictures of the process,

but basically, it required the install and removal of the weld mount

about 20 times. It is a trial and error process to get this thing

to fit. The issue is with the cut out on the bottom skin where the

weld mount must protrude. I used the Vans template to make my

cut-out, but in the end, the hole needed to be enlarged at least 1/16"

in all directions. The hole also required to be elongated

(inward). I used my dremel tool with a sanding drum to cut a

little, install the weld mount, check for fit, take out the weld mount,

cut a little, install the weld mount, check for fit, .... You get

the picture. I also found that most of the holes in the weld mount,

where the bolts pass through, needed to be slightly enlarged. I

used some drift pins to align the holes where the wings will attach,

then slide the weld mount AN bolts into position. The plans call

for AN 4-12A bolts, but these are not long enough. I used AN4-13A

bolts

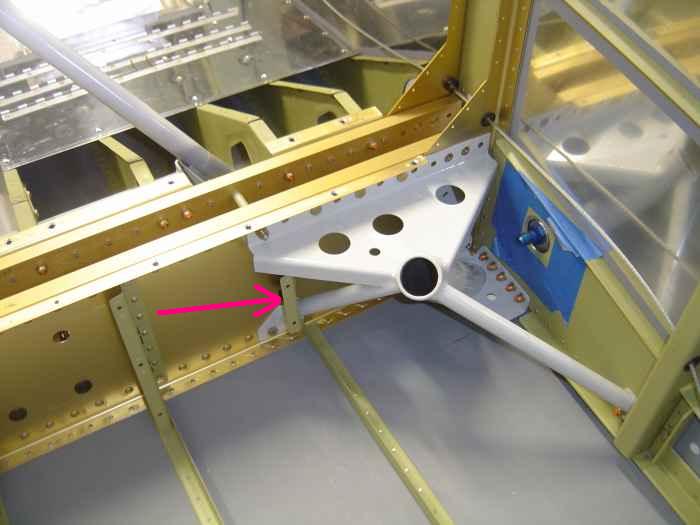

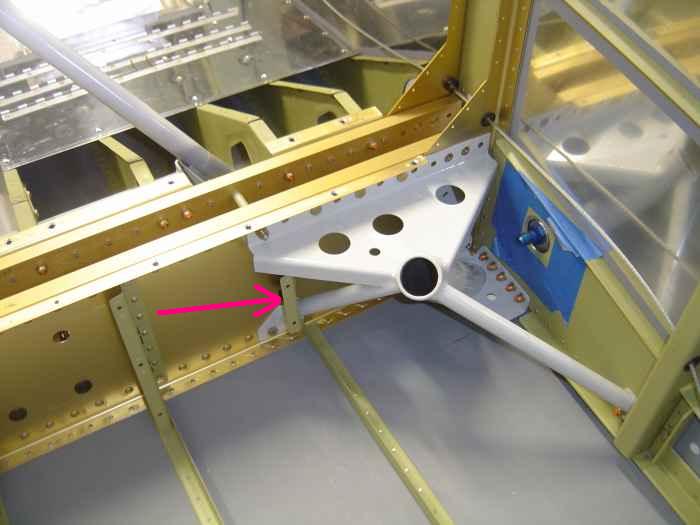

Here is a picture of left weld mount installed. The arrow is

pointing to the front cover bracket that needs to be removed when

fitting the weld mount. |

|

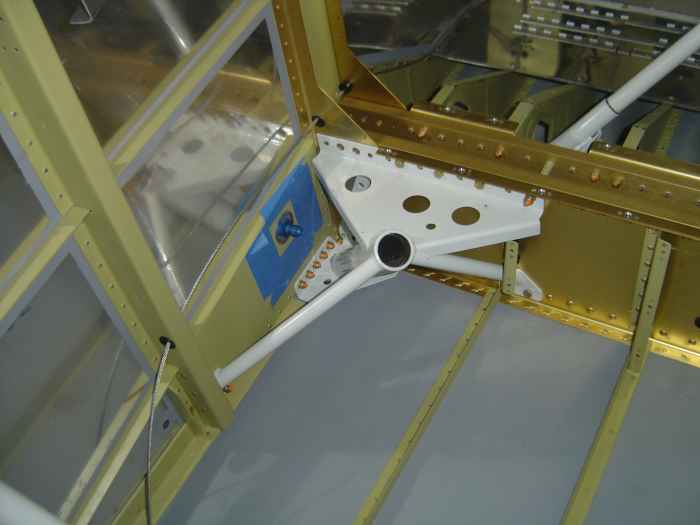

With the weld mount bolted in position on

the center spar. The attach points to the lower longeron and side

web stiffener get match drilled.

I first drilled these with a #30 bit and then moved up to a 3/16"

bit. I used lots of Boelube here! |

|

Here are the landing gear weld mount bolts

installed through the lower longeron. |

|

Here are the forward weld mount bolts

installed. These get match drilled through the weld mount, but

because you can only get a drill bit on the first hole, the second hole

must be measured and drilled from the outside using the first drilled

hole as a reference. The holes are exactly 1" apart on center. |

|

Installed the right weld mount.

After knowing the process from the work on the left side, this one went

much faster. |

|

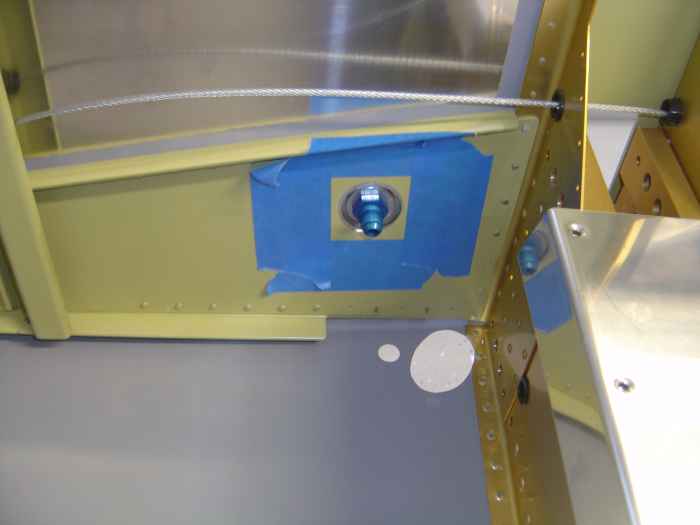

This is a shot of the side weld mount

attach bolts from the outside. Yes, the fuel line bulkhead fitting

is facing the wrong direction. It is only in there temporarily

until I get a chance to prime the inside skin surface where I cut the

hole for this fitting. |