|

June

30 - July 3, 2006:

(10 hrs.)

Built these saw horses at 21.5" tall to support the fuselage center

section. At this height, I was able to use a standard saw horse

under the tail. Once the fuselage was stable, I removed the seat skins

and set the remaining rivets holding the outboard seat ribs to side

skins. Because I am using nut-plates to attach all the seat

bottoms, there were a few places where I did not have access to buck the

tails of solid rivets so I just used blind rivets. These will not

be visible when the wings are attached. |

|

There were a bunch of little odds and ends

for me to take care of... I decided to install the control stick

assemblies I had built earlier. The brackets that attach to the

aft F-704 require a washer and nut to be installed on the AN bolt in

between the F-704 assemblies. There is not enough room to reach a

hand in between the two F-704s. I used my washer holders

(available at Avery's) to place the washer, followed by the nut holder

(pictured). |

|

I used duct tape to hold a box-end wrench

on the end of a long stick so I could reach in between the F-704s and

hold the nut while I torqued the bolt end. |

|

Here I am in the plane for the first time.

To attach the control stick hardware, I need to get up and close.

I am glad I spent $30 to purchase the washer holders from Avery Tools.

These have proven to be invaluable, especially for the control stick

hardware where I needed to place several washers in a tight space. |

|

The final product after several

adjustments to get the sticks completely parallel.

I also took advantage of having the seat bottoms off to install a few

more nut-plates that I did not get the first time. |

|

Miscellaneous work continues... I set the

AN470 rivets that attach the baggage compartment ribs to the F-706 |

|

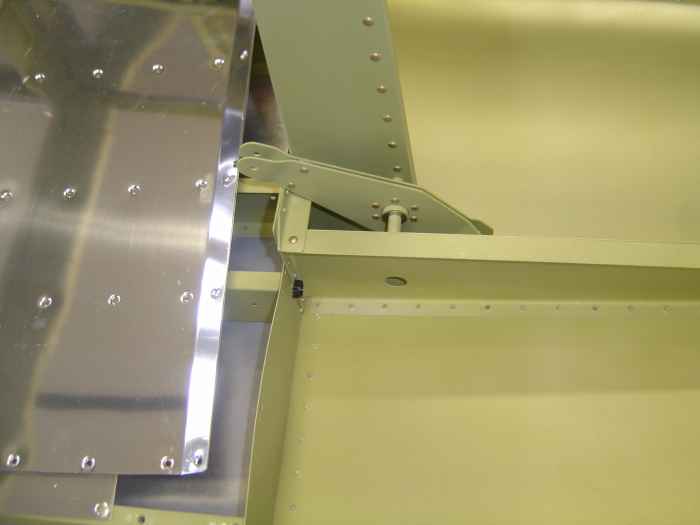

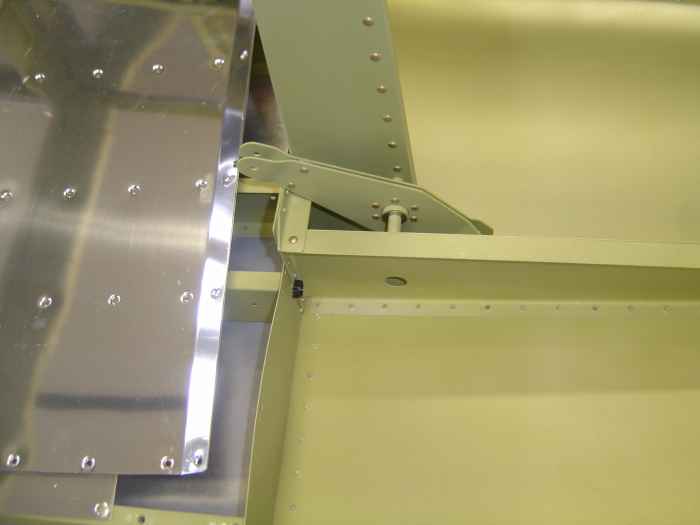

Some time back I had already build the

elevator bell crank, now I was finally able to install it. (those

of the seat bottoms just laying in the baggage compartment) |

|

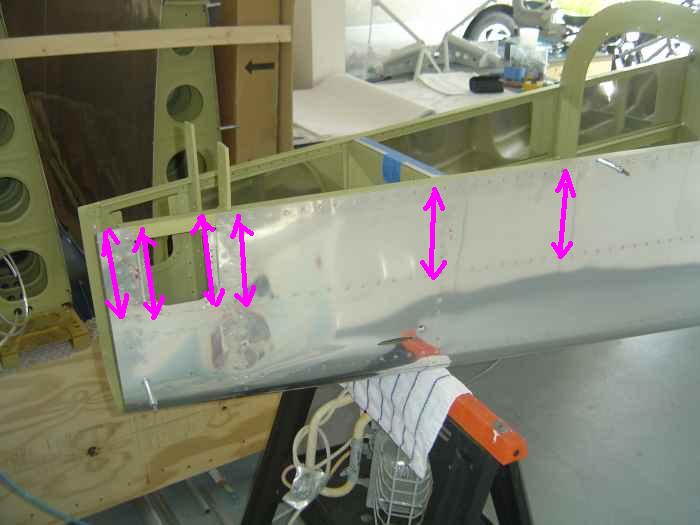

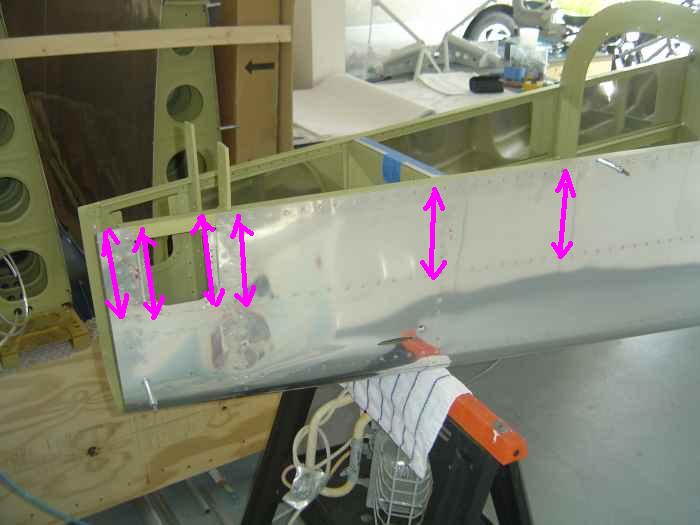

I shot all the remaining bulkhead to side

skin rivets on the left and right side of the aft section. |

|

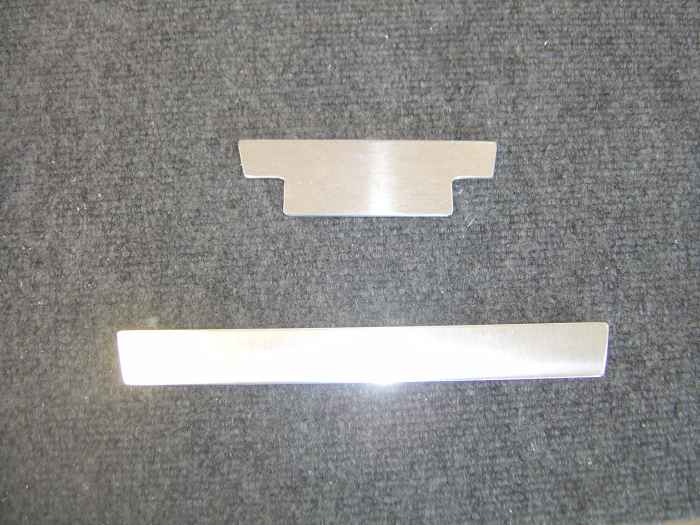

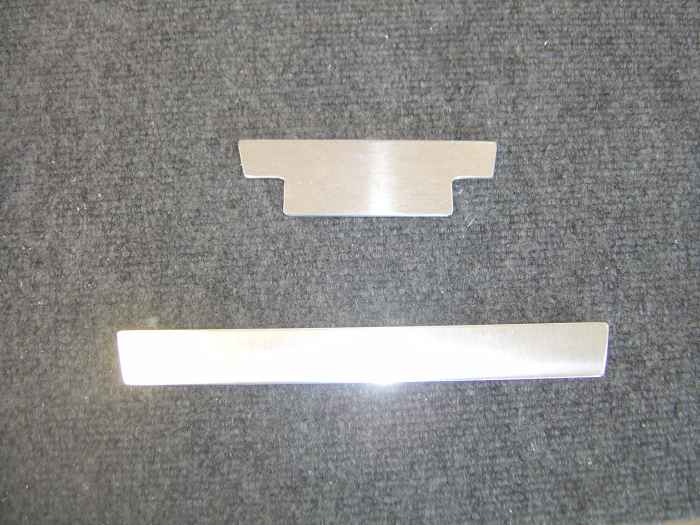

Before I can begin fitting the aft deck, I

needed to fabricate these spacers that will sit underneath the deck. |

|

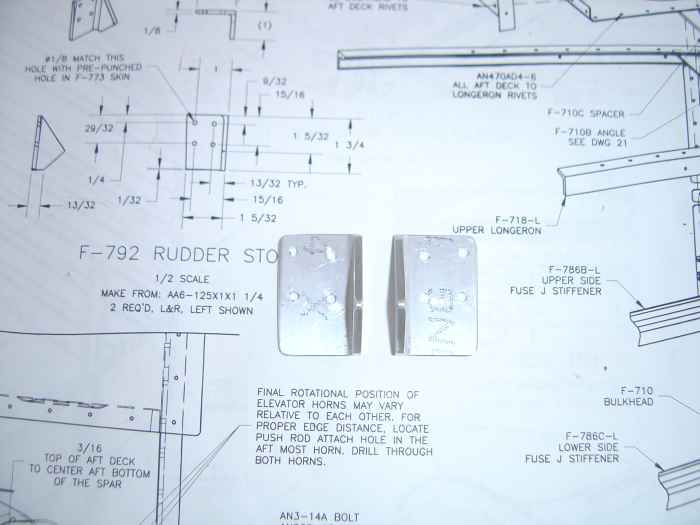

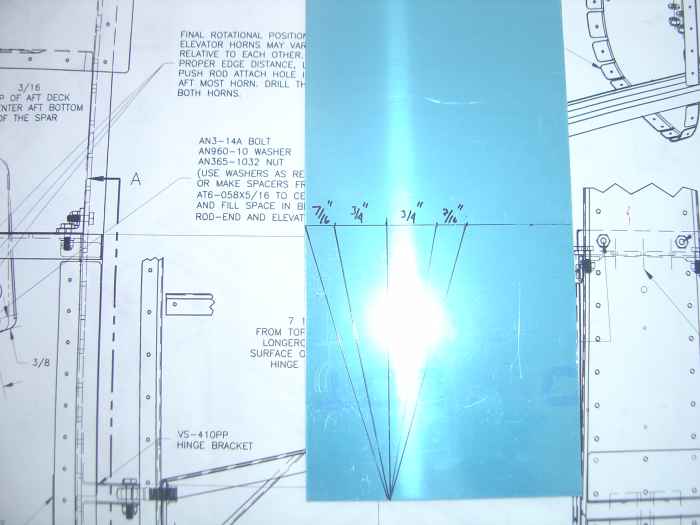

I also went ahead and fabricated the

elevator stop. Seems like it would be easier to build and fit this

during the aft deck assembly. |

|

Here are the spacers taped in place so the

wont move while match drilling the aft deck. |

|

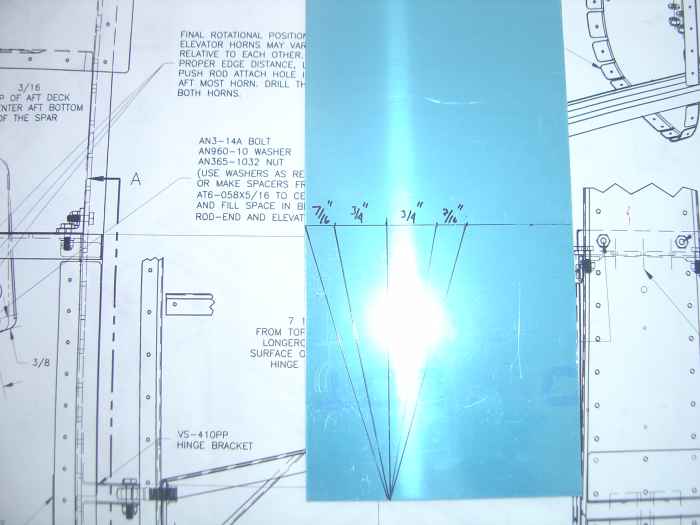

Aft deck gets clamped in place and

everything is checked for level. With a little adjustment and some

tightening of the clamps, the digital protractor reads level (0.0) |

|

The longerons at the center section should

also read level. If they do not, then some shimming is necessary.

To avoid any twist in the fuselage, it is critical everything is square

prior to drilling the aft deck. |

|

Here I am checking for level across the

seat back. It is close but not perfect. However, I found

that because the F-705 is still not completely attached to the fuselage,

it is not the best thing to use for leveling across the longerons.

I ended up placing a level across the longerons as at the center section

and then putting my digital protractor on it. I got things to

level out completely (0.0) in this fashion. |

|

With things level and plumb, I drilled the

aft deck |

|

After a deburring session, I primed these

parts using the Napa self etching primer. Since these parts all

had a nice Alclad finish, I did not think it was necessary to use the

AKZO primer. |

|

I figured it would probably be best to

address some of the aft fuselage work prior to installing the aft deck

because of the easier access.

Here I am laying out the rudder cable exit fairings. This

.20" aluminum will be cut out and bent on the lines to form the first

fairing. |

|

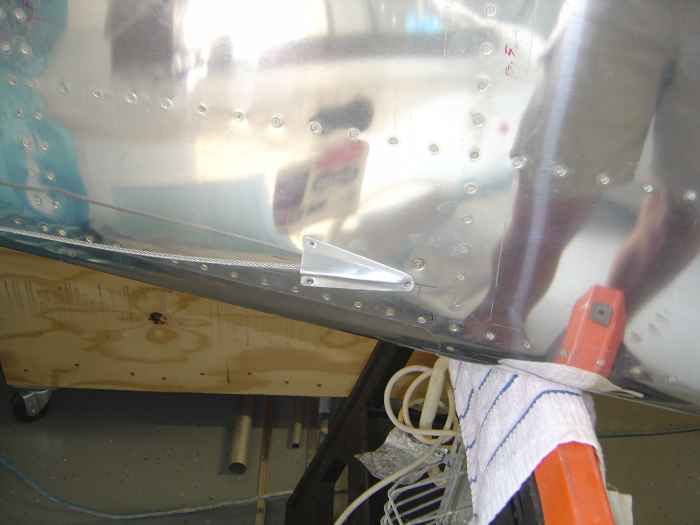

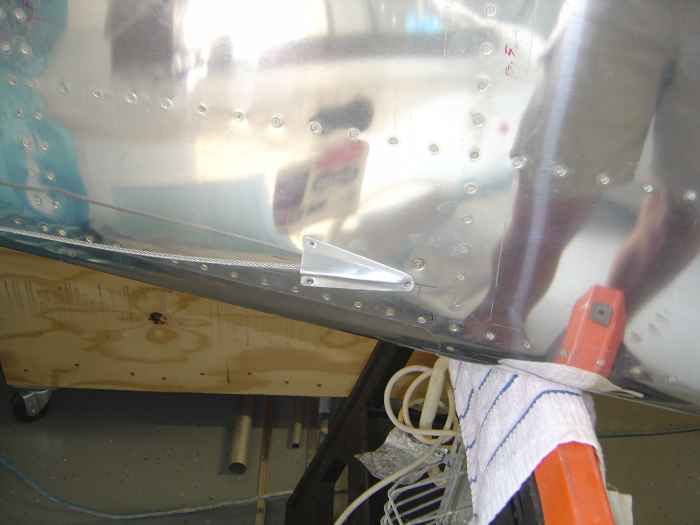

Here is the fairing completed and

installed. |

|

I also ran the rudder cables and secured

them in the specified location per Vans. This is a shot of the

inside of the aft section where the right side rudder cable exits the

fuselage. |

|

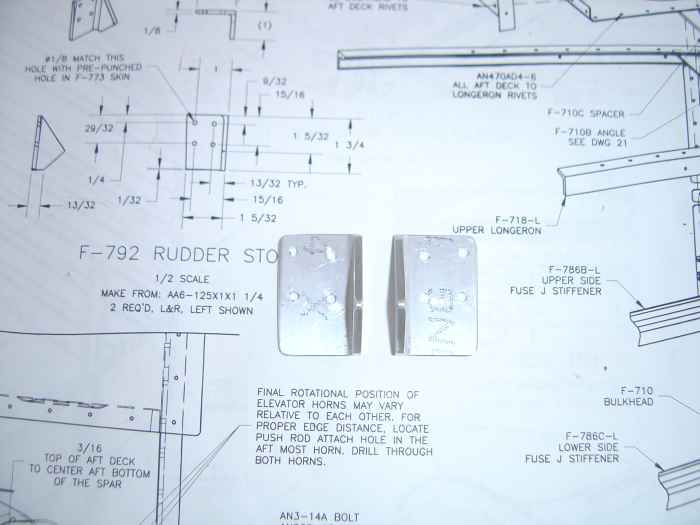

Next I fabricated and installed these

rudder stops. |

|

Here is the right side rudder stop

installed. |