|

November

25-26, 2006:

(4.0 hrs.) I was hoping to get a lot done on

the plane over the Thanksgiving holiday, but that got nixed when Kristy

found out I would be traveling for work the next 3 weeks. I had to

put in some good family time.

I did manage to find a few hours to get the

brake and rudder pedals installed.

Here I have installed the brake pedals in the

rudder pedal assembly, attached the entire assembly to the fuselage, and

hooked up the brake lines to the pilot brakes master cylinders. |

|

Next, I needed to get the brake reservoir

mounted so I could run the rest of the brake lines. I used the

call out on the firewall plans for where the reservoir mounts.

Hopefully, this will not interfere with any of my engine specific

mounting needs. Anyway, I measured and marked the holes.

There are two holes that get drilled through the firewall and the top

stiffener for AN3 attachment bolts. There is a 1/2" hole that

needs to be drilled where the reservoir will attach to a nylon fitting

in the cabin. I used a step drill to make this hole. |

|

Here is the reservoir mounted. It is

the first thing I have attached to the front side of the firewall! |

|

The lines for the copilots brakes and up

to the reservoir are a nylon high pressure line. These are stiff

lines that require a brass nipple and sleeve installed on the ends so

that they can be used with compression fittings. To help get the

brass nipple and sleeve installed, I softened the ends of the lines by

placing them in boiling water. |

|

With the compression nut and sleeve on the

line, the brass nipple is inserted into the tubing about 5/32". |

|

Next, I slid the compression nut and

sleeve down on the nipple end of the tube and applied pressure on the

nut, forcing the nipple the remainder of the way into the tubing and the

sleeve at the same time. Worked like a charm. |

|

I ran the high pressure nylon lines from

the pilot brakes to the co-pilot brakes and up to the reservoir.

Done deal |

|

December 2, 2006:

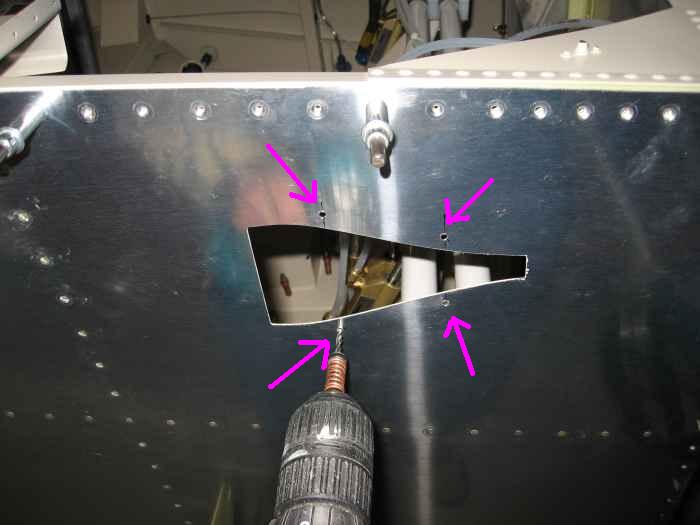

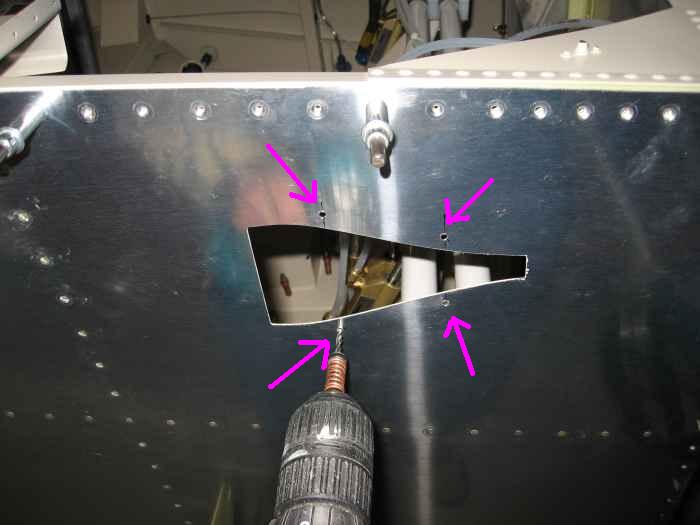

(1.0 hrs.) Decided it was about the right time

to get the Naca vents installed. Some people ProSeal these

on, others rivet them. I decided to ProSeal them and also use a

couple rivets to pull the skins snug to the vents while the ProSeal

sets.

I measured and drilled four holes for keeper

rivets on both side skins. With these holes drilled and deburred,

I held the Naca vents in place and matched drilled them using the newly

drilled holes in the skins. The Naca vents were then machine

countersunk to accept the skin dimples. |

|

The holes in the skins needed to be

dimpled for flush set blind rivets, but my hand squeezer would not reach

the holes. I figured I could use the dimple dies with a c-clamp

for this. I drilled a couple holes in some scrap hardwood to

accept the dies. |

|

Here I am using the c-clamp and the dimple

dies seated in hardwood to dimple the vent keeper rivet holes. |

|

Because the Naca vents are plastic, I was

worried about the rivets cracking the vents when they were set. I

fabricated some simple aluminum backing plates that the blind rivets

would grab a hold of. |

|

I mixed up some ProSeal (brought back

memories of building the tanks), iced the vent edges, and riveted them

into place.

Here you can see the vents in place. These will get some scat

tube attached and run to vents mounted on the panel. |

|

I used the left over ProSeal to seal up

some of the openings on the firewall recess. |