|

July 4 - 9, 2006:

(10 hrs.)

Checked everything for level one more time and then riveted the aft

deck into place. I also riveted the semi-circle bulkhead (F-710 ?)

into place. The direction say to slide this into place after the

top skins are on, but it seems easier to do it now. |

|

Fabricated the F-705 gussets. For

the sliding canopy, that amounts to creating the radius on one end. |

|

These gussets slide into a slots on the

center canopy deck that were cut some time back. After match

drilling the gussets to the F-705 and longerons, I deburred everything

and set the rivets. |

|

To set the rivets in the center canopy

deck, I needed a thin bucking bar to reach underneath the decks rolled

bottom. My 'c' yoke from the hand squeezer made a good bucking

bar. Just add a little duct tape to keep from scratching things up

and you are good to go. |

|

Here is the bucking bar being held into

place under the canopy deck. |

|

Canopy decks all riveted |

|

After the decks were attached, I used a

file followed by a Scotchbrite wheel on my die grinder to bring the

decks outer edge completely even with the side skins. Note that I

have not primed the decks (or arm rests). I have decided to not

prime any parts that will be receiving interior paint until I determine

what kind of finish paint I will be using. I have heard that the

AKZO primer is not the greatest to put a finished coat over, and

many people end up sanding it down. I would like to avoid that

additional work. |

|

Next I match drilled the forward canopy

decks |

|

And the forward upper firewall gussets |

|

Used my hand squeezers and c-shaped yoke

to set these flush rivets in the F-706 and elevator bell-crank rib. |

|

Next I fitted and match drilled the seat

belt shoulder harness attach point. Just clamped them to the

longerons and match drilled the holes. |

|

I had previously cut the J channels for

the fuselage tops, so all I had to do was place them into position.

I used a little duct tape to hold them in place until they are match

drilled. A center line was drawn down the length of each J channel

which will be used for aligning the center of the channel thru the top

skin pre-punched holes. |

|

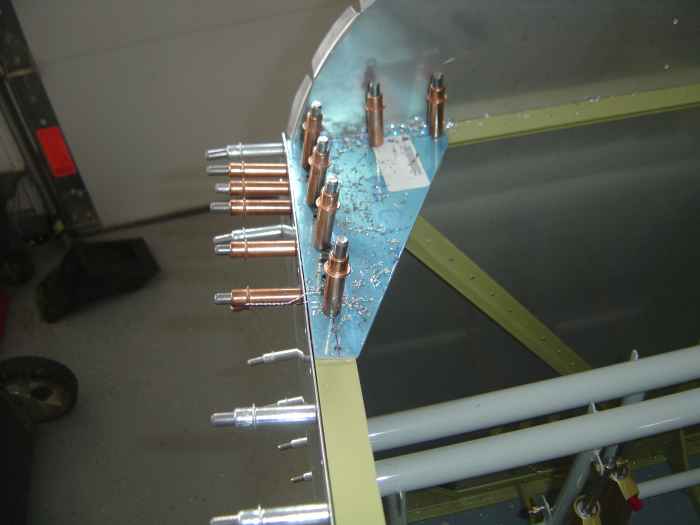

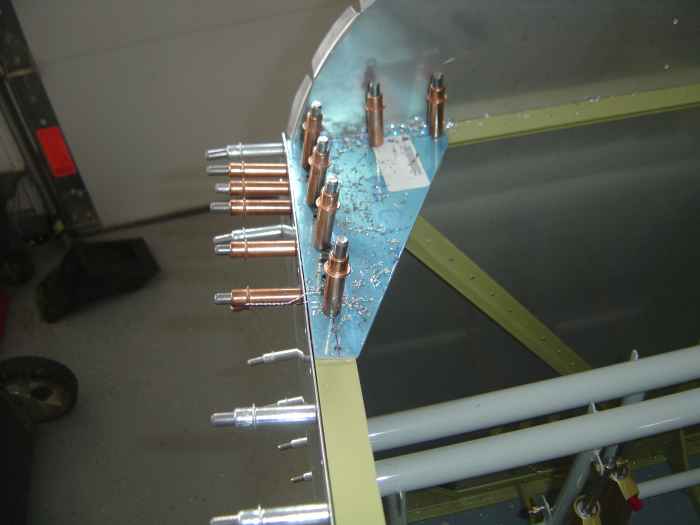

After clamping into place and drilling the

F-706 and F-707 bulkhead gussets into place, I cleco'd on the aft top

skin.

Arrow in picture is showing on of the F-706 bulkhead gussets |

|

I don't remember the part number, but I

installed this top center rib. It gets cleco'd to the F-706 and

then the top skin. The back end of this rib gets attached to the

F-707 with a little clip which you will see in a second. |

|

Drilling the aft top skins to the J

channels. |

|

Front top skin is cleco'd into place |

|

Here is the aft end of that rib that gets

attached to the F-707 with a little clip I fabricated out of some .032

3/4 x 3/4 aluminum angle. With the front top skin on the right

side peeled back, I used my right angle drill attachment to match

drill the holes in the clip. |

|

Next all the top skin holes were match

drilled.

Starting to look like something.... |