|

November

10-12, 2006:

(8.0 hrs.) There were a few things I needed to

complete on the center console before I could declare it finished.

Here is a shot of the console from rear. The forward top of the

console will attach to the panel. The hole in the top aft section

of the console will have a hinged lid and act as glove box. The

plan is to upholster the console using the same leather as will be used

for the seats. It should look really sharp. |

|

Here is picture from the from of the

console. After I took this shot, I took the console out and

removed the throttle quadrant. I needed to adjust the quadrants

friction lock, and short then screws that attach the quadrant to the

console. |

|

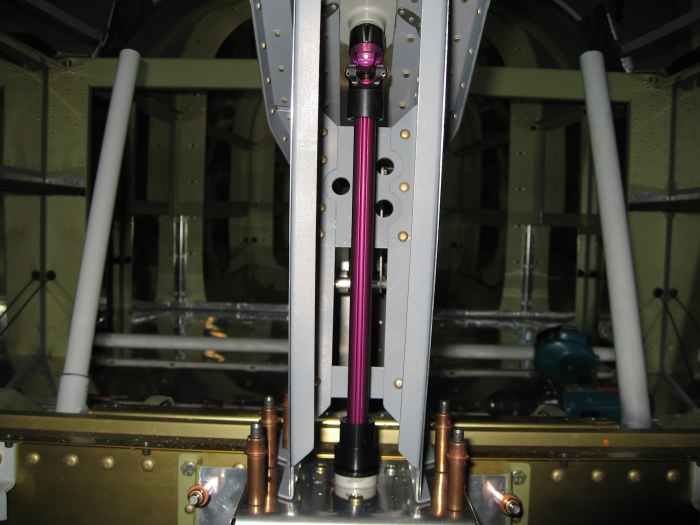

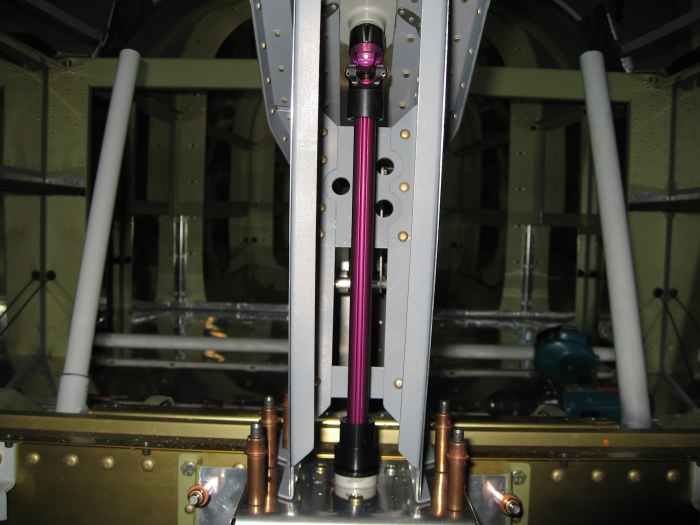

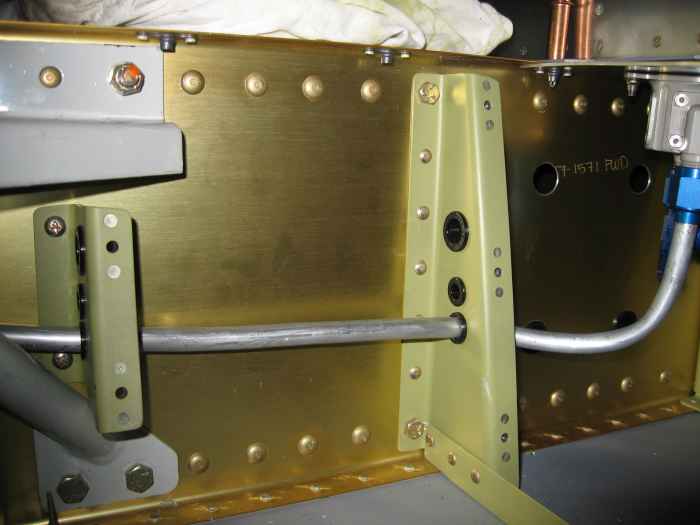

Another item I had to address on the

console, was the fuel valve extension mechanism. Here you can see

I have installed the fuel valve extension coupler (bottom), union joint

(top), and extension rod. The rod had to be cut to the proper

length. |

|

With the console completed, I moved on to

the fuel vent lines. The first thing I did was work on the

bulkhead fitting for where the vent line exits the fuselage. I

chucked the AN straight 1/4" fitting into my drill press and then ran a

file along the thread to remove them. I followed that by running

some fine sand paper along the newly formed nipple to smooth things out.

You have to make two of these. One each for the left side and

right side vents |

|

Next, a 45 degree angle was cut on the end

of the fitting using my band-saw. |

|

The bulkhead fittings where then installed

into the forward bottom fuselage with the 45 degree cut facing forward.

I think the purpose here is that positive pressure on the vent line will

be created by ram air. |

|

Now on to the vent line itself. It

is takes a strange bending path from the wing root area up to the

longerons and back down the firewall to the bulkhead exit.

I started by placing the fitting nut and sleeve on the tubing (do

this prior to flaring and bending!) and then flaring the end. You

need to use a special aircraft systems flaring tool that creates a 37

degree flare. |

|

Since this is only a 1/4 tubing, I opted

for using a spring and hand bending the tubing. It worked out very

well. |

|

I started by attaching the fitting nut to

the vent inlet at the wing root, and then bending the tubing around the

lower stiffener and behind the rudder cable. Adel clamps were used

to hold the tubing in position as I continued along the path. |

|

Here is where the tubing bends to follow

along the longeron and under the upper firewall-to-longeron gusset. |

|

The tubing then travels down the inside

edge of the firewall to the lower longeron where it get held in place

with another Adel clamp. From there, it is a simple bend down to

the ventline bulkhead exit fitting. |

|

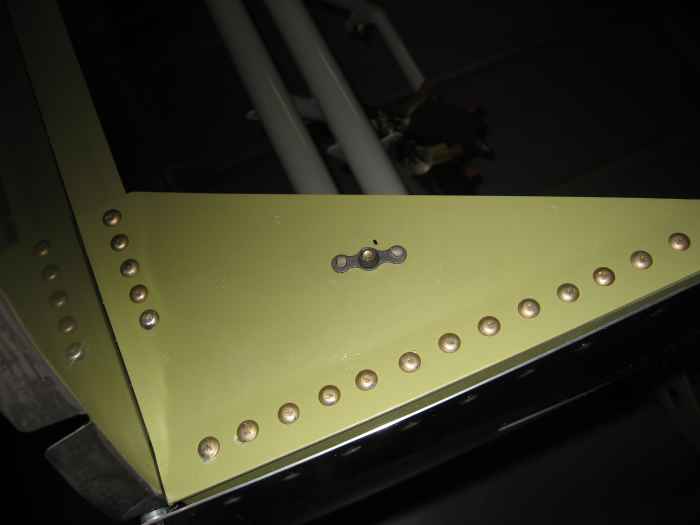

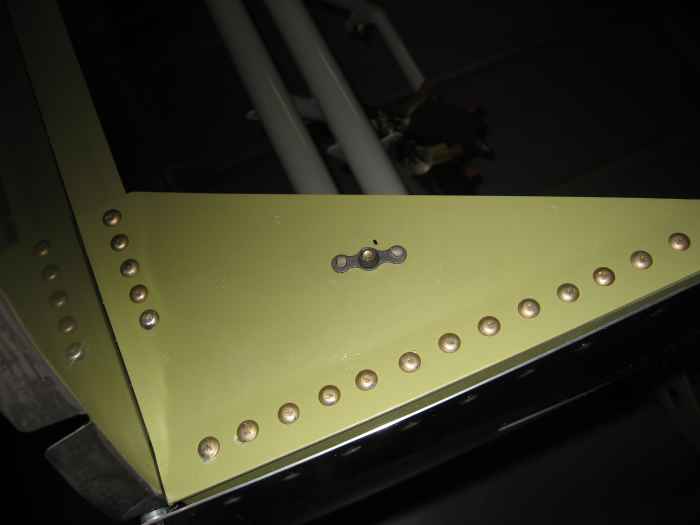

For some reason I did not have nut-plates

installed on the upper longeron-to-firewall gussets, so I installed

those at this time. |

|

The fuel supply lines were the next task

at hand. The fuel line is 3/8" in diameter and much thicker

walled. I found that a hand spring bender did not work very well

on this stuff.

First things first. I slide on a nut and sleeve and flared the

end of the tubing. |

|

Using my bending tool, I created two

opposing bends as close as possible to the end of tubing.

Here I am making the first bend, which is slightly over 90 degrees. |

|

After the second bend is made, you should

have a 's' curve in the end of the tubing that looks like this. |

|

Next, approximate the length of tubing

required to get from the wing root to the fuel valve and cut to length.

Create a gentle curve in the remaining tubing. This curve is

required to allow you to feed the free end of the tubing through the

gear mounts |

|

Hear I am feeding the the free end of the

tubing through the landing gear mount and into the lower grommet of the

front cover bracket. Once you get into this position, you will

need to use your hands to straighten the leading end of the tube a

little bit at a time as you feed it toward the fuel valve. |

|

Eventually, the wing root end of the fuel

line will look like as pictured. This is the left side fuel line

as it passes through the landing gear mount. |

|

Here is the left side fuel line as it runs

through the forward cover bracket grommets and up to the fuel selector. |

|

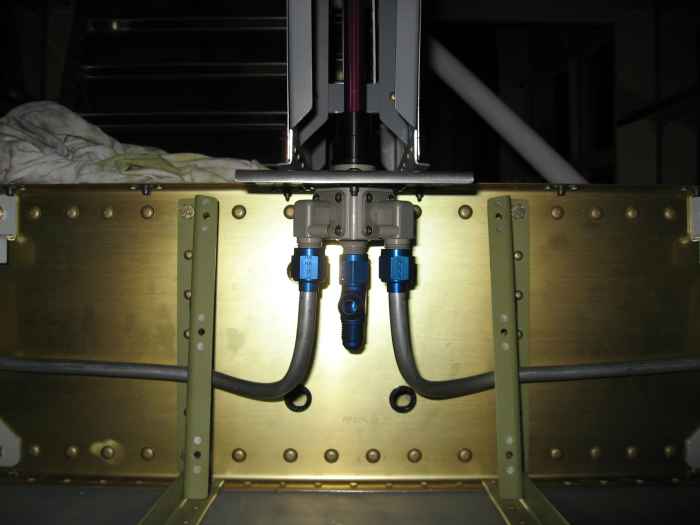

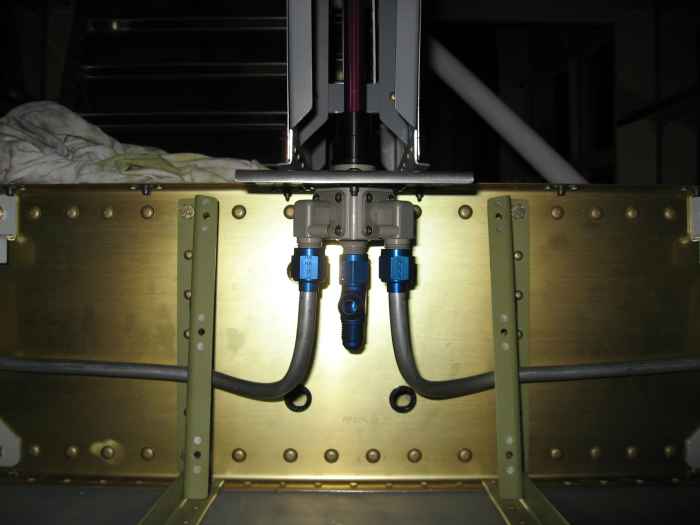

Here is the Andair fuel selector with fuel

supply lines attached. |

|

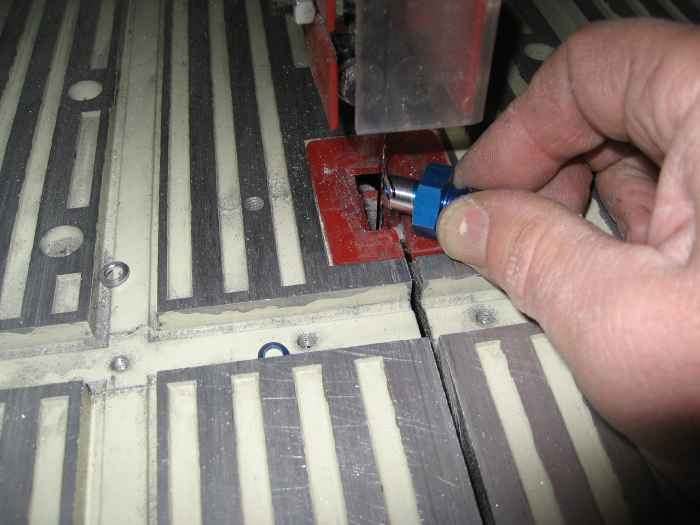

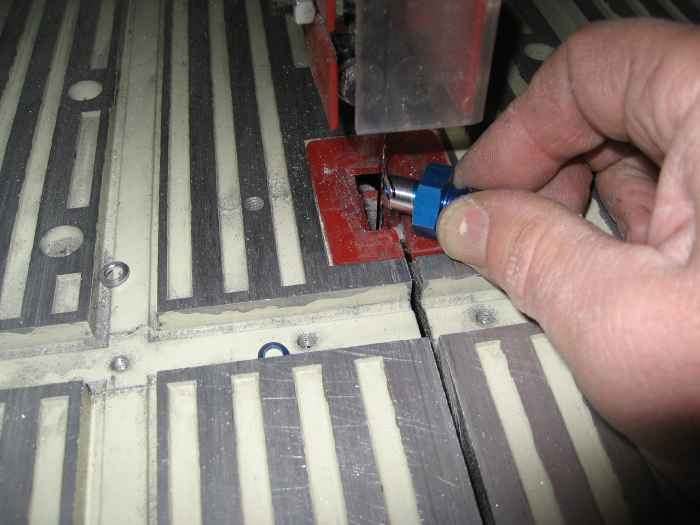

I had a couple of miscellaneous items to

finish up. Here I am installing the single leg nut-plates on the

seatbelt crotch-strap attach points. |

|

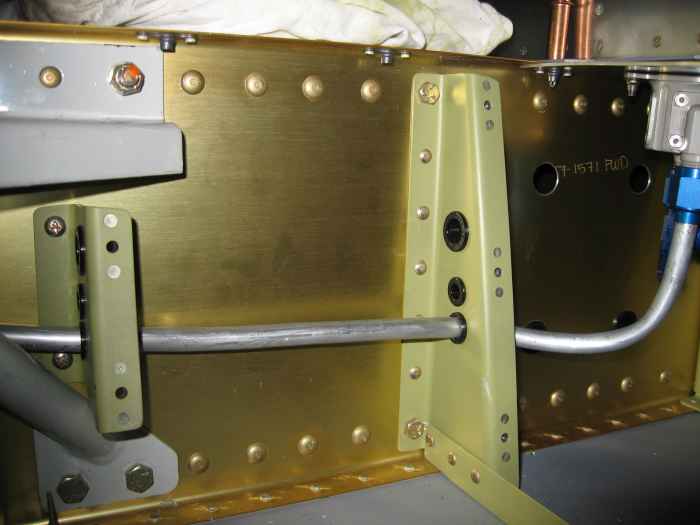

I riveted the rudder pedal center mount

support bracket to the firewall. |

|

I wanted to get the brake lines installed,

but ran out of time. I only managed to install the AN fittings on

the firewall. |

|

I also installed the brake line AN

fittings that exit the fuselage at the gear leg mounts. I

put a some RTV under these fittings to help hold them in place and seal

things up from the outside. |