|

May 3, 2005:

(1.5 hrs.) Mixed up another batch of ProSeal and covered the shop

heads of all the rivets on the rear baffle |

|

I ordered the tank test kit from Van's.

It comes with this end cap for the for the fuel pick up line.

Before attaching it, I put some EZ Turn on it (substitute for Fuel

Lube). This will help ensure a good seal. |

|

This is the can of EZ

Turn I purchased from Aircraft Spruce. You don't have to use much

of this stuff, so this can will probably last a life time. |

|

Also part of the tank test kit is this

adaptor that attaches in place of the fuel drain. This adaptor has

a tire valve on it so you can pressurize the tank with a compressor or

any hand pump. |

|

I bought 10' poly tubing from home depot

and attached it to the vent line with hose clamp. |

|

The tubing hangs down to the floor and

then runs up another 4 feet. I screwed a 1x2 board to the work

bench and used duct tape to hold the tubing to the board. I then

filled the tubing with colored water until its level was half way

between the floor and the tank. |

|

Since the fuel cap does not form an air

tight seal, Vans recommends covering it with duct tape. |

|

Next the tank is pressurized to 1 PSI.

The way of determining 1 PSI is to pressurize the tank until the

distance between the water level on open end and tank side of the tubing

is 2'3" [ this specification comes from Vans in the tank kit ]

I marked the board at height of the the water level and documented

the temperature, 69.3 F. As the temperature decreases, so will the

water level and vice versa.

Next, I brushed soapy water over all the rivet lines, joints, and

connections. I quickly saw I had a leak coming from under the duct

tape the was covering the fuel cap. I removed the tape and brushed

more soap water over the surface. Yep, air was leaking from the

fuel cap. |

|

I removed the cap and wrapped it with a

latex glove and then reinserted it. I then covered that with duct

tape and re-pressurized the tank. I tested everything again

with soapy water and could not find any leaks. So far so

good.

I came back out to the shop an hour later and noticed that the water

level had dropped about 2 inches. I also noted that the

temperature dropped about 8.5 degrees. I decided I would let it

sit overnight and check it the next day after things warmed up.... Sure

enough, the next day, when the temperature reached 69.3, the water level

was where it need to be. Wow, it is nice to know this tank

done! |

|

May 4, 2005:

(1.5 hrs.) In preparation for priming the tank external

facing ribs and baffle, I wiped everything down with MEK. I then

used a Scotchbrite pad and ruffed up the surface. One more good

cleaning with MEK and it was ready for paint. But, before I

do that, I better check for fit on the wing... Yep, fits...

After a simple masking job and quick shot with the

paint gun, the tank was primed and ready for installation. I think

I will let it sit overnight before I install it.

I spent about an hour giving the shop a thorough

cleaning. |

|

May 5, 2005:

(1.0 hrs.) Did not have much time to work on the plane today, but

I did manage to install the tank on the right wing. Everything

seemed to line up perfect.

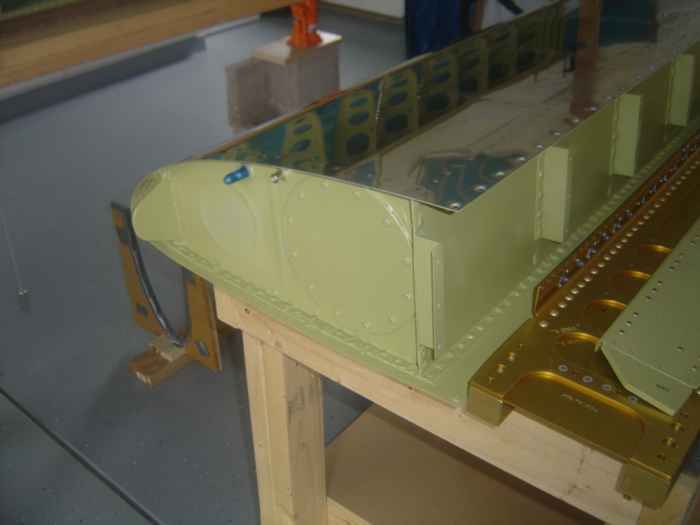

Here is a shot of where the tank and leading edge

join. The picture makes it look like there might be some pillowing

between the screws, but there is not. It is a nice clean fit.

I went ahead and installed all the tank to spar

and leading edge screws. I also torqued all the spare to z-bracket

AN3 bolts. |

|

Here is a picture of the right wing with

the tank and leading edge installed. My plan is to rivet on the

top skins next weekend. |