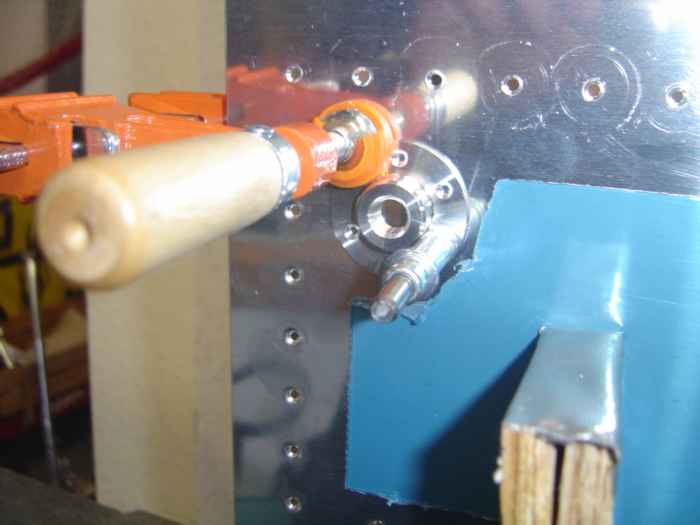

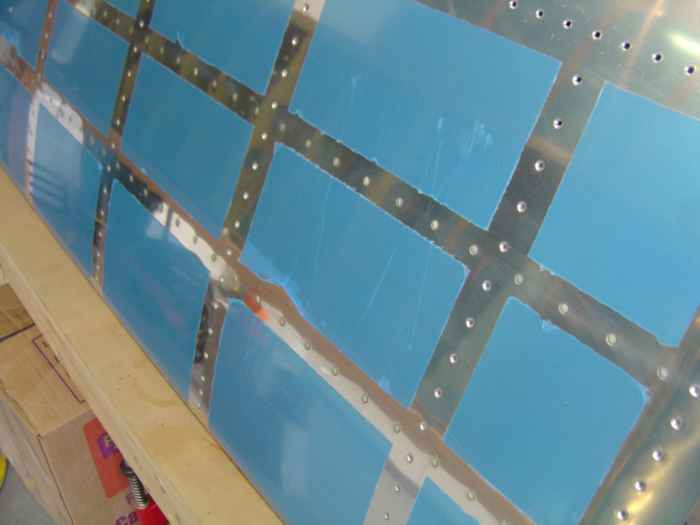

Notice on the floor a caulk gun. I modifed this gun to squeeze the ProSeal out of the SEMCO tubes of sealant I purchased from Vans. This worked really well. All that need to be done was to grind down the diameter of the caulk gun plunger to fit into the SEMCO tube.