|

May 28, 2005:

(2.0 hrs.) ProSealed and riveted the outboard root rib

reinforcement plate... This was a simple matter of squeezing the AN470

rivets. I also spent some time covering all

the rivet shop heads on the tank ribs with ProSeal. I added

additional ProSeal on all the rib to tank skin transitions.

|

|

Next, I iced up the outboard root rib with

ProSeal and cleco'd it into place. I then used my hand squeezer to

set all the rivets. |

|

I ran the fuel sender wire from the

outboard fuel sender plate to where the inboard fuel sender plate gets

installed. The wire runs along the same path as the fuel vent

line. The wire meets up with a wire coming from the BNC

connection. The two wires get crimped and soldered to a terminal

connector. Having to reach down into the tank to do this is

difficult, but doable. Next, the terminal connector is attached to

the inboard fuel sender plate and covered with ProSeal.

Last, the inboard fuel sender plate is mounted into place. Note all

the extra ProSeal that I added to cover the rivet shop heads and the rib

flange to skin seem. This is definitely no longer a neat and tidy

finish. I am glad this is hidden from sight inside the tank. |

|

This is a picture of the fuel sender wire

running along the fuel vent line path. The wire is wrapped around

the vent line and fixed into place with a few strategically placed globs

of ProSeal. |

|

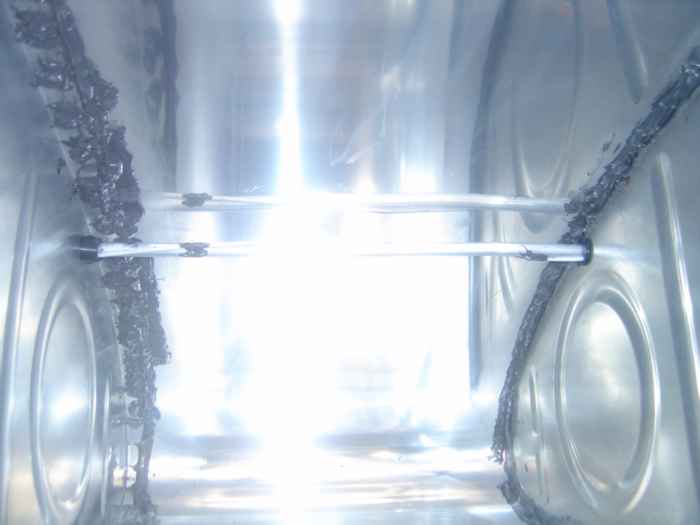

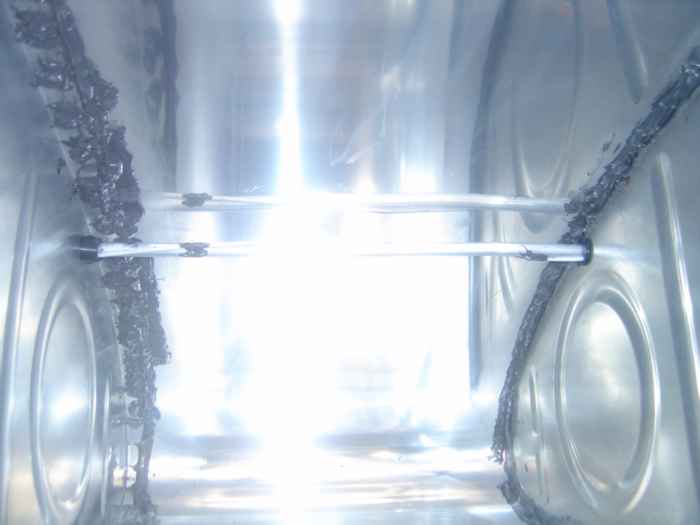

This is a shot of the outboard fuel sender

plate. |

|

Spent some some using a ScotchBrite pad to

roughen up the aft tank rib flanges and the rivet lines of the rear tank

baffle. I also got out all the parts and tools for the next big

ProSeal session. I use the dixie cups to soak the various size

rivets and screws in MEK prior to their use. |

|

May 29, 2005:

(3.0 hrs.) Today was the big day! Installing the rear

baffle on the right fuel tank. Because I was in a crunch to get

this done before leaving on a business trip, I decided to tackle this

job without a helper. First, I cleaned all

the mating surfaces, rivets, and screws with MEK, Next, I mixed

the ProSeal in a large quantity (~55 grams). I inserted the

ProSeal into a plastic zip-loc bag and cut the corner, making something

similar to a bakers icing tool. I then laid a bead of ProSeal down

over the tank skin rivet line (3/16" bead). I also laid a larger bead down on the

inside edge of the rear flange of the inboard and outboard ribs. For the interior

rib rear flanges, I smeared a 'small' amount of ProSeal around the rivet holes.

I added a nice big glob of the stuff in the corners of the end ribs. |

|

Next the rear baffle was slide into place

and all the rivet holes in the tank skin were cleco'd to make sure the

baffle to skin was squeezed tight. I also cleco'd into place the

tank z-brackets.

There are a lot of cleco's so I had to work fast! I next

removed every other cleco from the tank skin, inserted a rivet and then

used my hand squeezer to set the rivet (this is where a second set of

hands would of helped) Once this was complete, I

removed the rest of the tank skin cleco's and set those rivets.

Last, I move on to the rear baffle z-brackets. The brackets on the

center ribs take a blind rivet. To set these, I had to use my

cheapy pop rivet gun that I had ground down the nose on to fit up against the

brackets.

The z-brackets on the end ribs take solid rivets. I had to buck

these rivets because none of the yokes for my squeezer would squarely

reach these. This was easy work because there is great access for both

the gun and bar. |

|

In a final step, I mixed up a new batch of ProSeal and

attached the access cover. I used both the cork gasket and ProSeal

figuring that the cork gasket will help the cover break away if I ever

need to get into the tank. I would like to rejoice that his tank is

complete, but I really can't celebrate until I do a pressure test and

find it leak free (fingers crossed). I will do that this coming

weekend. |