|

December

7-9, 2007:

(4.0 hrs.)

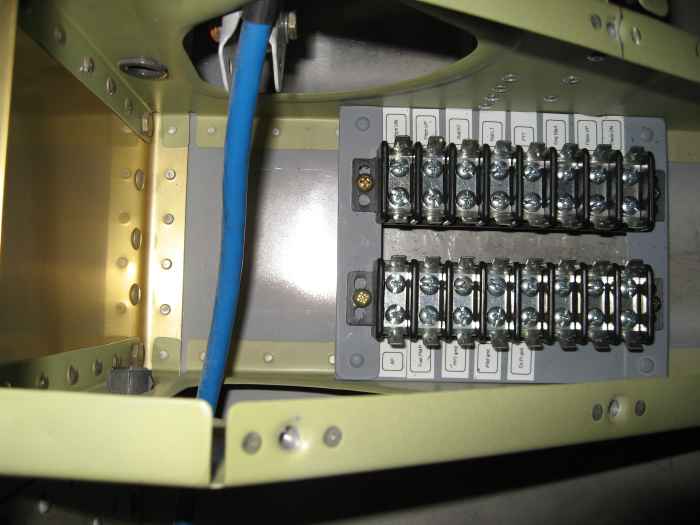

Played around running some of the first wires to the electrical

busses. Here I have run the wires to the Main bus and FADEC A bus.

I also ran the wires for the master/bat, aux/bat, ECU1 and ECU2 switches

switches. I cannot wire the panel ends of these up until I have

the panel and switches installed. For now, they will just hang

there. |

|

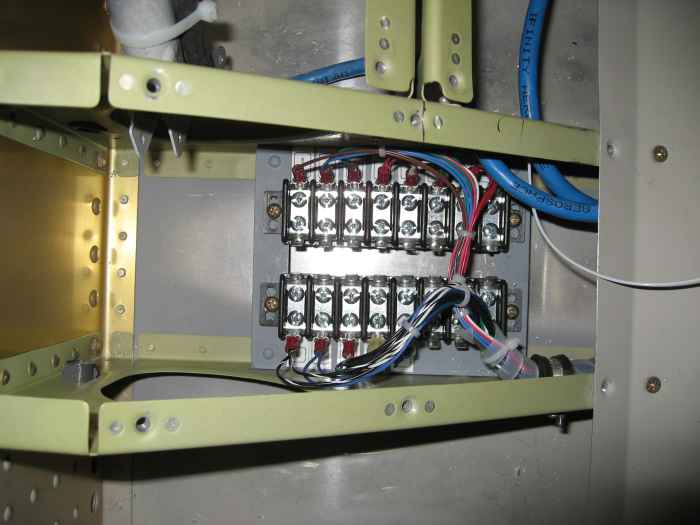

On the back side of the sub-panel I

created a service loop with the wires and secured them to the sub-panel

with an Adel clamp. This service loop will allow the buss panel to

swing down for service. |

|

Here is show of some of the wiring I did

on the front of the firewall. It is kind of hard to see, but the

arrow is pointing to the 6 AWG wire I ran from the main battery

contactor to the main bus. Along with the wire run, I also ran

smaller gauge wire runs for the FADEC A bus, always hot Bat Bus, and

battery contactor switch. I used an Adel clamp on an ECU mount

point to help secure the wires. |

|

Here is the right side of the firewall,

where I made similar runs for the auxiliary bus, FADEC B bus, etc. |

|

Here is some of the wiring behind the

firewall for the auxiliary bus, FADEC B bus, etc. wire runs.

Note I did made a similar service loop on these as well. |

|

December

14-16, 2007:

(8.0 hrs.)

Installed these quarter turn fasteners on the front of my fuse panels

(2 per panel), to allow easy access the fuses. I picked these up

from Aircraft Spruce. |

|

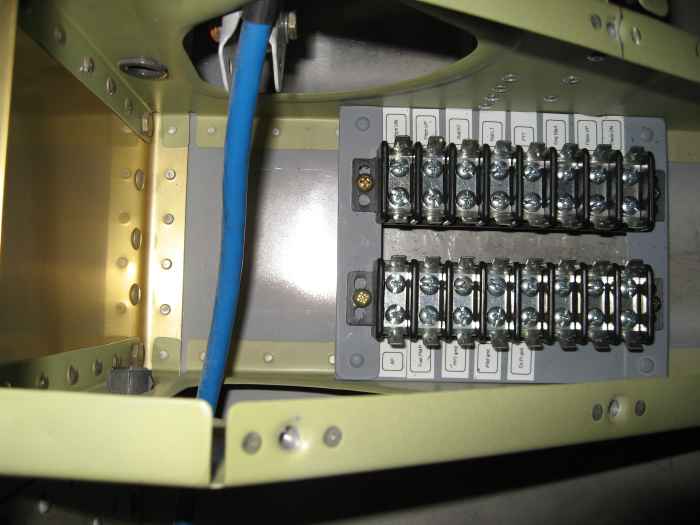

Fabricated this terminal strip holder

which is installed between the seat ribs under the pilot seat.

These terminal blocks are for receiving all the wires coming out of both

the pilot and co-pilot sticks.

The terminal strip hold is made out of four pieces of aluminum stock

and is riveted tot he seat ribs. I installed nut-plates to receive

the attachment bolts that go through the terminal blocks. I marked

all the locations of the various wires using my label maker. |

|

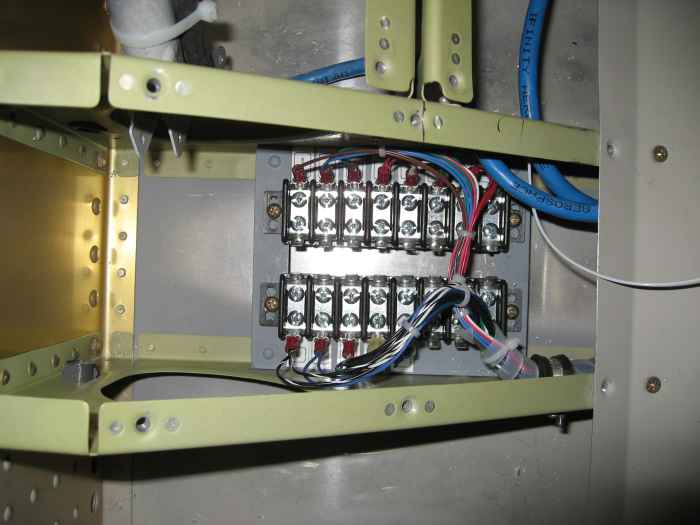

I then began the wiring process. I

will be running both the pilot and co-pilot wires in parallel. I

isolated all the co-pilot grounds, except the push-to-talk (PTT) so that

I can rig a co-pilot stick kill switch on the panel. This will be

good when I am flying with small kids and do not want them accidentally

deploying my flaps or something. I will always keep the PTT

active... at least that is my current thinking. |

|

Here are the terminal blocks installed and

the stick wires all tidied up. |

|

Next, I decided to install my flap

positioning system. This is an after-market product from Show

Planes that allows you to deploy 10, 20, and 30 degree increments of

flaps with a single, double, or triple push of the momentary flap

switch. It also positively stops the flap motor when the flaps are

fully retracted. It was actually quite easy to install.

Kind of hard to see in this picture, but the system installs by

fitting over the standard Vans flap actuator. |

|

The flap positioning system also includes

a small controller box which I mounted to the inside of the vertical

upright structure of the seat backs bulkhead.

Here you can see the control unit installed. I installed molex

connector between the control unit and the flap motor in the event that

I need to pull the motor out some day for service (I hear this typically

is required). The rest of the wires are just temporarily bundled.

I will probably install a second molex connector for the wire runs to

the stick terminal blocks and then clean this bundle up.

|

|

While I was working on the flap

positioning system, I decided to install this swivel LED eye-ball light

behind the seats to shine in the baggage area. |

|

|

|