|

January 6-7, 2007:

(2.0 hrs.)

I decided to go with an the

Trutrak Digiflight II VSGV auto pilot. I ordered the servos so

I could get them installed now. I will not order the auto pilot

brains until I am ready to work on the panel.

Here are the two servos. Pitch and Roll |

|

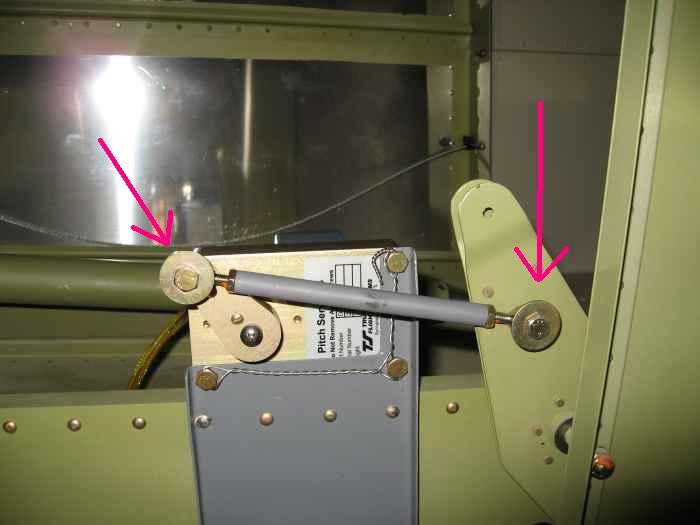

The pitch servo comes with the required

hardware to attach it to the elevator bell-crank rib.

Its a relatively simple process. I measured the setback for the

bracket to the bell-crank and identified the bell-crank rib rivets that

needed to be removed. With the rivets removed, I match drilled the

holes to the pitch servo bracket. The bracket and push rod were

then deburred, cleaned, prepped and primed.

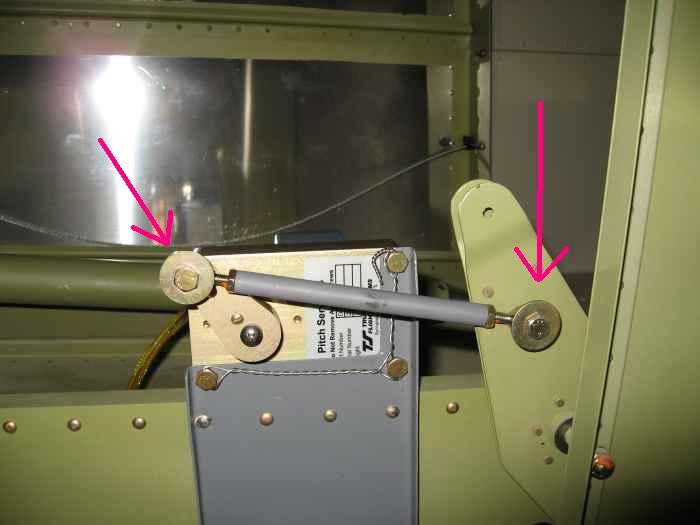

Here you can see the bracket with servo and pushrod attached all

attached. |

|

This is a shot showing the bracket setup.

I added a few extra attachment rivets lower on the bracket and then left

out the rivets that would attach it to the bottom skin. It seemed

plenty strong with the extra rivets I used.

My pushrod was at an angle to the aileron bell crank (can't tell from

this picture). I checked a few other builders sites and saw that

they had the same issue. Trutrak indicates that it is not a

problem. Some builders have used spacers on the servo arm to

correct the angle.

Also note I safety wired the servo attachment screws. This was

my first real hand at doing this. In these pictures I noticed a

bit of slack around a couple of the bolt heads, so I will probably redo

the safety wire. |

|

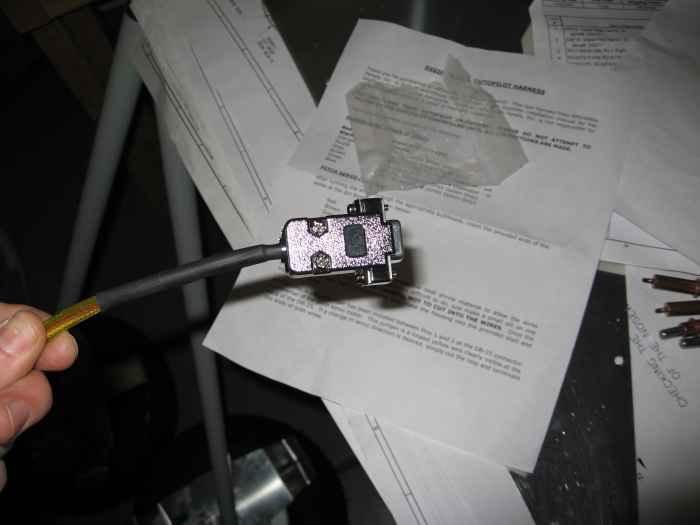

I went ahead and ran the wiring harness

for the auto pilot servo. I bought a pre-fabricated harness from

Affordable Panels, so it was just a matter of running the wires and then

putting on the DB connector.

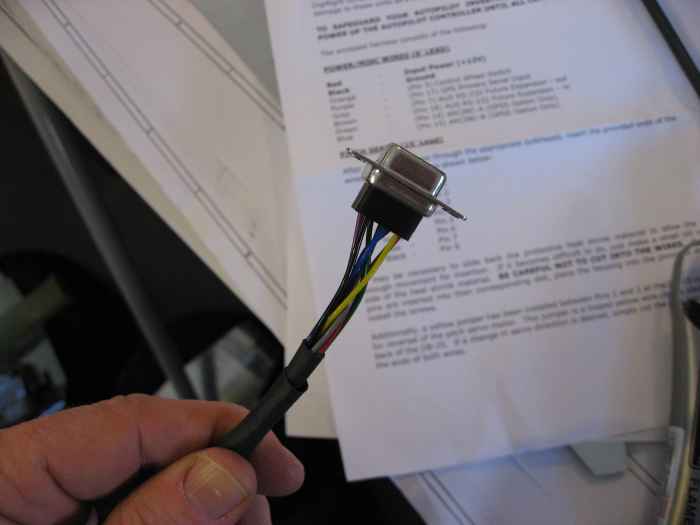

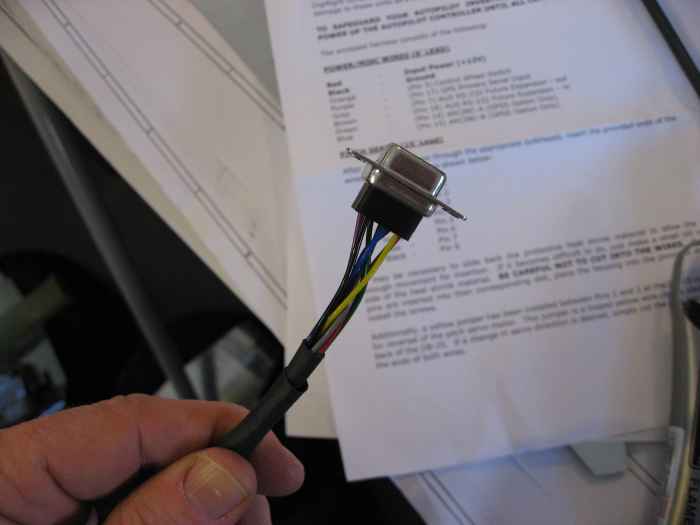

Here I have installed the wires into the correct pin positions of the

connector |

|

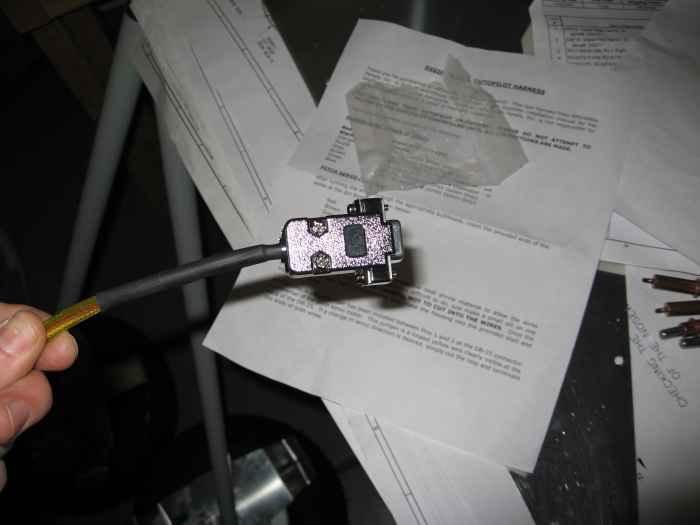

Added some heat shrink and installed the

connector case. Done. |

|

After viewing a few more builders sites, I

decided that I would change my pitch servo push rod setup slightly.

First, instead of using the large safety washers as on offset for the

rod-end on the bell-crank as per Trutrak instructions, I decided to use

regular washers in that position. I the used the safety washers

for their intended purpose on the outside of the pushrod ends

(pictured). |

|

I also added 3 washers between the pushrod

and the servo arm to decrease the pushrod's angle to the bell-crank.

I had to replace the AN3-7 bolt with an AN3-10 bolt to accomplish this.

I felt this provided a happy medium between putting a full spacer in to

make the push rod run straight with the bell-crank (which Trutrak

recommends against), and leaving the current angle in which was causing

a little bit of binding. |

|

November 20

- December 3, 2007:

(12.0 hrs.)

I have been spending quite a bit of time working on my electrical

system design. Since I will have an electrically dependent engine,

as well as all electric panel, I have decided to install a highly

redundant electrical system. I am going with a dual battery and

dual alternator setup. I will be closely following the Bob

Nuckolls Aeroelectric

Z-14 design. My electrical design can be found

here. Ad

|

|

I decided to go the non-traditional route

and use fuses instead of circuit breakers. I basically bought into

Bob Nuckolls reasoning on the subject in his book the 'AeroElectric

Connection'.

With fuses in mind, I bought some fuse blocks from BandC and then

fabricated these hinged panels that will sit under my panel. |

|

Here is the left side panel installed via

a hinge to the sub-panel. The reason for the hinge is to provide

easy access for troubleshooting and changing fuses. I do NOT

expect to do this in the air, only after I am down safely on the ground.

The left side fuse panel houses the FADEC A Bus and the MAIN Bus. |

|

Here is my left side fuse panel. It

houses the FADEC B Bus, AUX Bus, and BATT Bus |

|

Here is the left side panel swung up in

the closed position. I still need to find a camlock fastener that

I can use to hold the panels in the closed position securely. |

|

Installed the B&C LR3 regulators for my

alternators. I have two of these regulators because I have two

alternators.

Here is one of the regulators installed on the right side rib near

the firewall. The second one is installed in the same position on

the left side. |