Spent a lot of time on the plane but mostly trying to figure out what I wanted to get done next. There are so many little jobs I can tackle at the moment now that I have the finishing kit and the firewall forward kits in the shop.

I decided that with the engine on order, it probably makes sense for me to focus on getting the firewall ready for the engine. That said, I did have the canopy roll bar laying on the floor and wanted to get it mounted and out of the way.

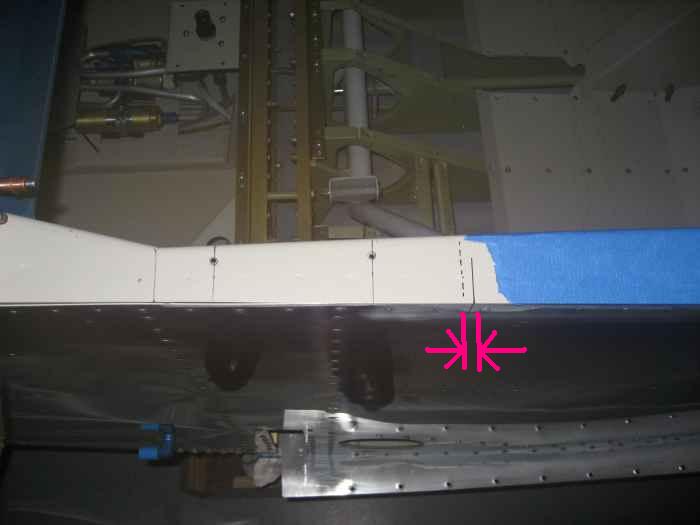

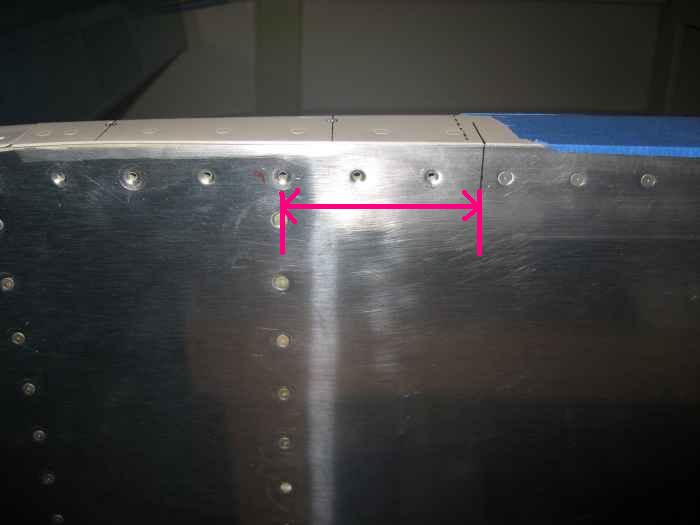

The roll bar gave me fits. Mainly because the measurements on the 'full scale' plans were not matching what I was measuring on my canopy deck. The plans have you measure back from a rivet on the side skin (I think 2 5/8") [pictured].. this gives you the aft position of the roll bar.