I have not been as consistent with updating this web site. I guess that is how it goes when you start getting to a point in the project where you can see the end.

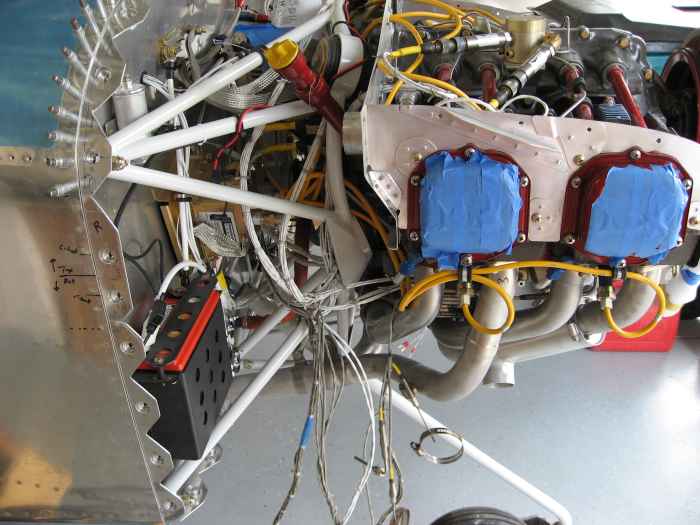

I have been doing a lot of work on the baffles getting them to fit the plenum, setting up the oil cooler mount, and adding reinforcements. Here you can see the left side baffle and the bracing I have fabricated to hold my oil cooler solid.

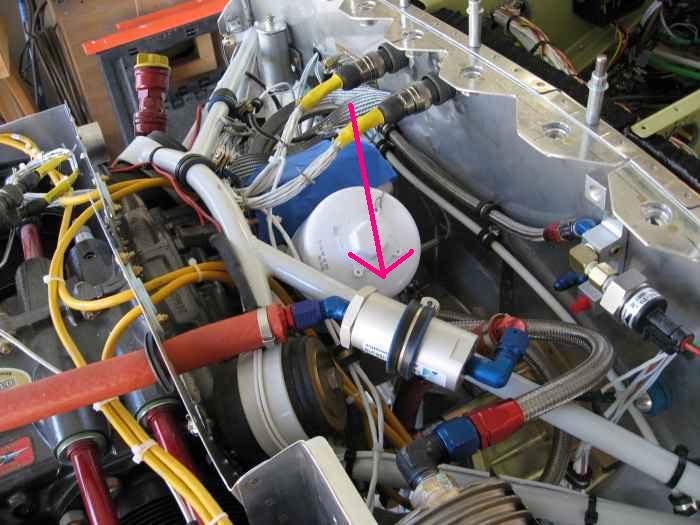

The arrow is pointing to a portion of the oil cooler brace that I need to trim back to provide adequate clearance for the cowl.

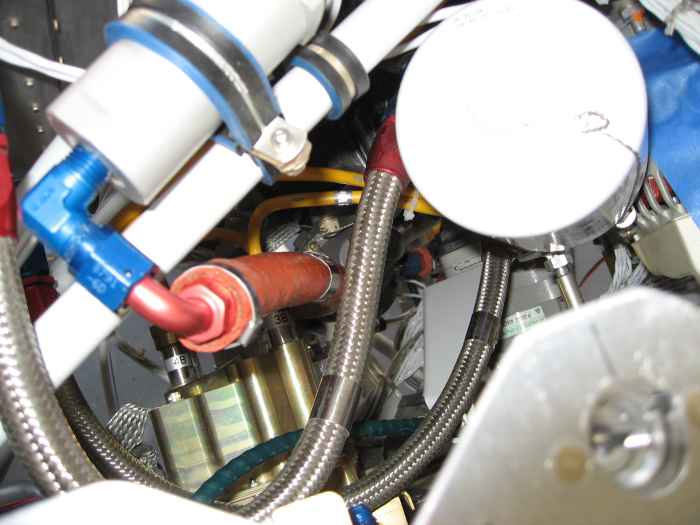

I also installed the EGT probes. This involved drilling a hole in the exhaust pipes about 2 13/32" down from the top of each exhaust pipe flange. The probes then get held in with hose clamps.

Here I have added some fire-sleeve over the throttle cable to help protect it from exhaust pipe heat. I also installed a small shield over the cylinder 1 exhaust pipe. Things are pretty snug over this pipe.

The fuel lines going into and out of the filter were fabricated by me using Aeroquip hose and fittings.