|

December

16, 2007 - January 5 2008:

(8.0 hrs.)

I decided to check and see if the throttle and prop control cables I

ordered a while back from Van's would fit my setup with the control

quadrant in the center console. The cable I ordered were 55"

First things first, I needed to drill out the firewall swivel eyeball

pass-through's to match the diameter of the cables. I used my

drill press to achieve this. |

|

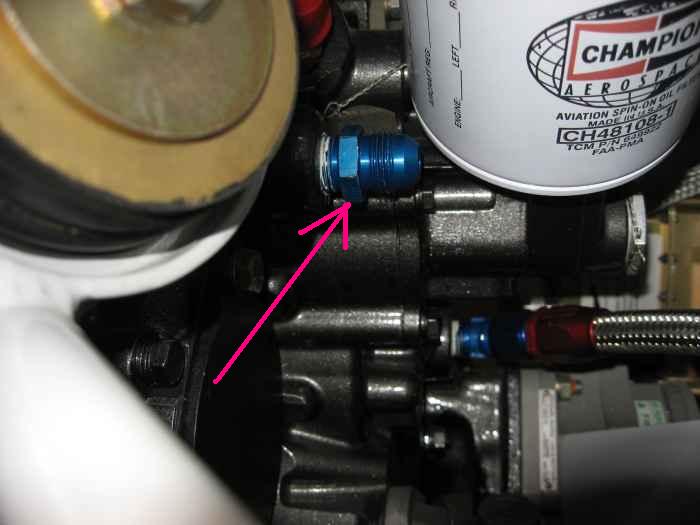

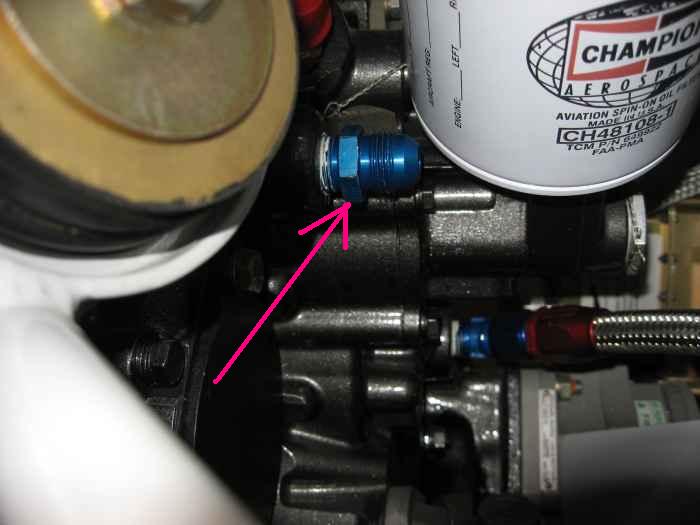

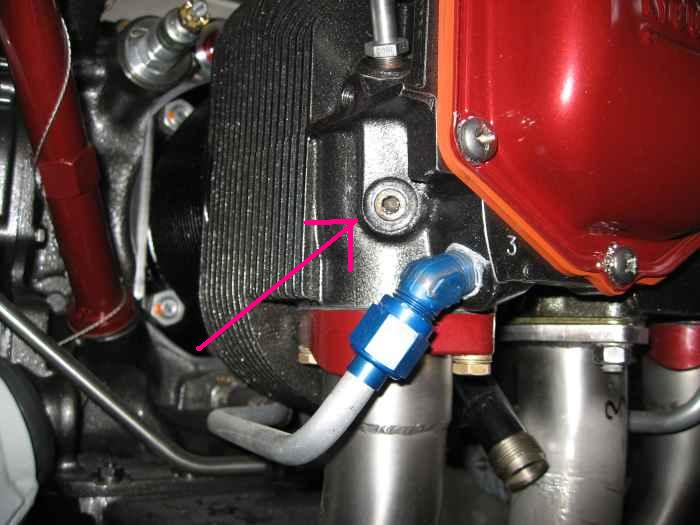

Here I have run the prop governor control

cable. The arrow is pointing to the swivel eyeball pass-through.

It is kind of hidden in this picture below the electrical pass-through.

The 55" cable worked great for this application. However, I was

not so lucky with the throttle control. I did not take a picture,

but it ended up being a couple inches short. I am going to have to

order a 60" cable for that. |

|

I cleco'd the top skin on and finished the

fabrication of the camlock attach points along the top of the firewall

for the top cowl. It turns out the the work I had done prior on

this was wrong. I messed up on a couple of my measurements and my

spacing between the camlocks was uneven in a couple places.

|

|

Next, I laid the top portion of the Van's

stock panel in place to see how things were going to fit. Not

good! To my surprise, the cowl appeared to be almost 2

inches short. In this picture you can see the big gap between the

front of the cowl and the back of the prop spinner. Well, after

much head scratching and number of calls to Vans and MT propeller, I

think what happened is that MT built me a spinner and hub for the Sam

James cowl setup, which uses a longer cowl. Now I need to decide

if I want to wait for a new prop to be built (the last one took 5

months), or replace my stock cowl with the Sam James unit. |

|

Since I could not work on fitting the

cowl, I decided to do some miscellaneous work. I installed the oil

cooler return line fitting on the engine. And what do you know, another

problem. The straight fitting suggested by Vans interferes with

the oil filter so that I cannot put the hose on the end. At least

this is an easy fix, I can use a 45 degree elbow instead. I just

need to order one. |

|

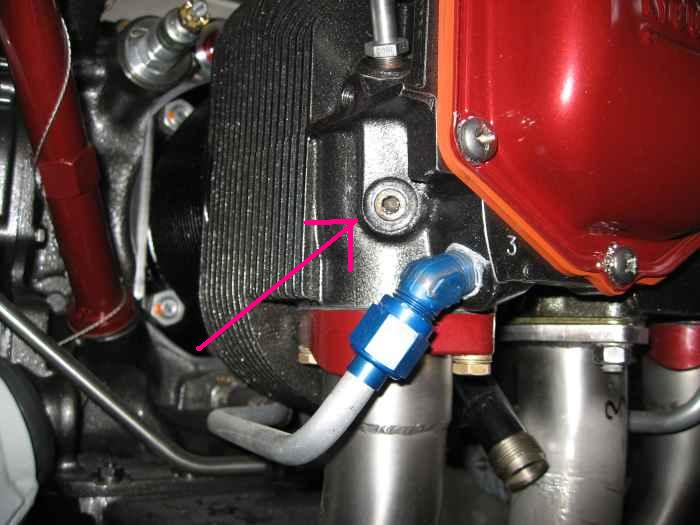

I put a plug in this hole meant for the

manifold pressure connection. I don't think I will be using this

with the FADEC. I believe it measures and reports manifold

pressure differently. We will see... |

|

I ran the fuel supply line from the

bulkhead fitting on the firewall to the engine driven fuel pump. |

|

Installed this engine driven fuel pump

over-flow line. It meanders down to the bottom of the firewall and

exits out the bottom skin. |

|

Here is the where it exits. I just

opened up one of the bottom skin rivet holes and popped the aluminum

tubing through. |

|

While I was working down here, I decided

to squeeze the few bottom skin attach rivets along the bottom of the

firewall between the two exhaust pipes. |

|

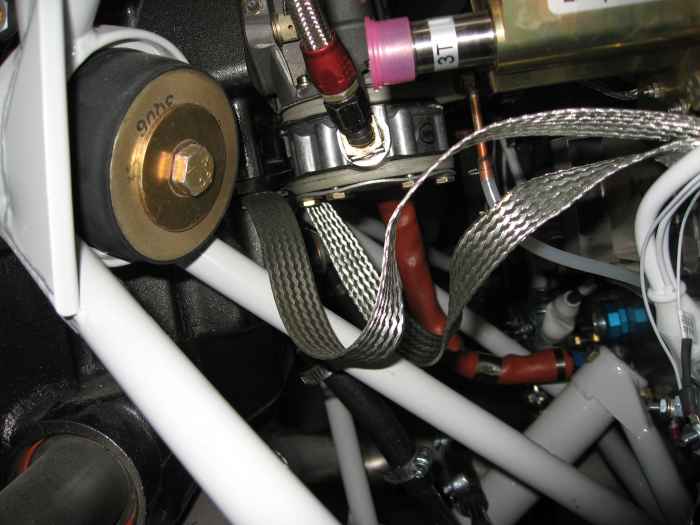

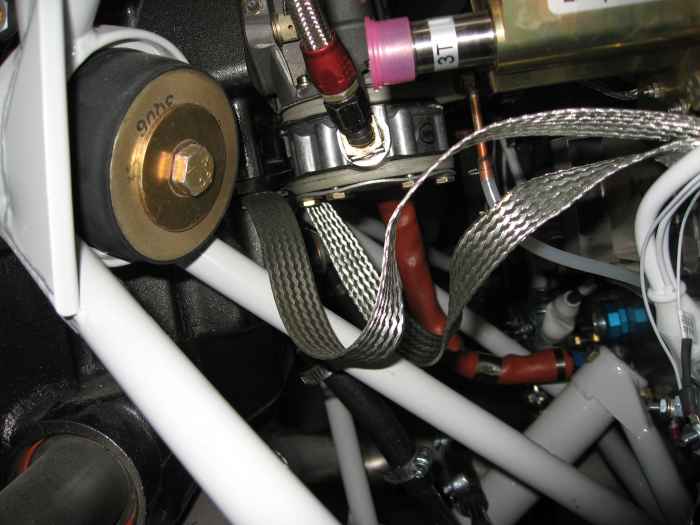

I installed a brass bolt through the

firewall and the ground bus. The ground bus on the front side of

the firewall (not pictured) is larger, so this bolt actually passes

through it.

This will be used as one of the grounding points for the engine.

The Aersance FADEC system calls for 4 engine ground strap wires, so I

need some places for these to attach. |

|

Here I have run two ground straps from two

separate mount screws for the auxiliary alternator. These connect

to brass bolt I just installed |

|

I had a spare mounting point (nut-plate

installed) on the left side of the firewall just below the ECU. I

figured I would use this for the other engine ground straps. |

|

These two ground straps then ran to two

bolts on the sump case in front of the engine driven fuel pump. |