|

February 2 - 9,

2008:

(8.0 hrs.)

I started out working on something that I thought

would be a simple job, but turned out to be quite an ordeal. I

wanted to install the sniffle valve on the bottom of the sump.

There is a set-screw that gets removed and the sniffle valve installed.

My set-screw was extremely tight. I got it to turn about 1

revolution and then it seized up. Worse, the allen head began to

strip. What to do? Well, after much deliberation over a couple of

days, I decided on this: Heat the sump area up around the

set-screw plug with a blow torch (pictured), bought a Allen Head socket

so I could apply some up-word pressure, and walla, the plug came out.

The internal threads still looked good, so I was happy. |

|

Next part of the ordeal... The sniffle

valve when installed was so close to the exhaust, I could not get the

tubing for the drain line installed. That's no good. Again,

much deliberation and study. I ended up purchasing a 90 degree

brass fitting from Ace and that allowed me to move the sniffle valve out

and to the rear. |

|

I installed some protective fire-sleeve

around the drain line where it was close to the exhaust. I think

this will work. |

|

Here is a shot of the drain line running

to the firewall. It is secured to the engine mount frame via two

Adel clamps |

|

Well, a while ago I decided to go with the

Sam James cowl rather than the Van's stock cowl. As such, I

decided I would also install the Sam James plenum. I already have

the Van's baffle kit, so I will use that as a starting point to my

plenum installation. Sam James provides some plans to build your

own baffles, but it seems like the Van's kit will save me some time.

Normally, you fit and install the Cowl before you start on the baffles

and plenum, but I don't have my cowl yet, so will try to get as much

done on the baffles as I can.

I started by installing the side baffles and the bolt hole attachment

doublers plates. Here the right side has been deburred, fitted,

and match drilled. The same was done for the left side |

|

This is a picture of me fitting the back

right baffle. This sucker has proven to be pain. First, I

had to remove the oil dip stick to get better access to one of the

baffle attach points. The blue tape is covering the dipstick hole.

This baffle comes from Vans with a small bent tab to that is used to

attach the baffle to the engine case right near the dipstick. I

found this tab to be hindering my fit, so I cut it off. I then

built an attachment plate out of some .040 (that's what is cleco'd into

place in the picture). This seemed to work out pretty well. |

|

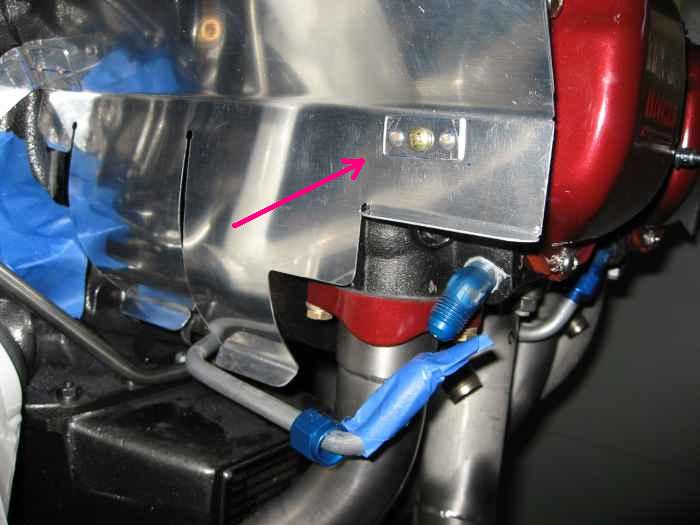

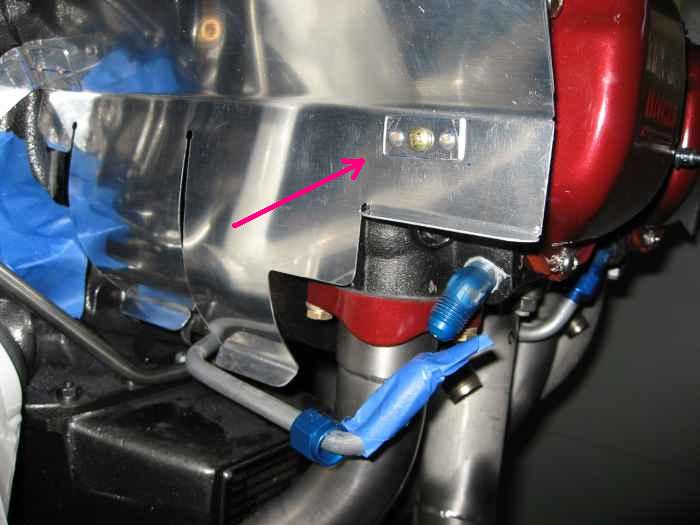

This is another shot of the right rear

baffle. I had to disconnect the oil line to the #3 cylinder to

make the fitting process easier. As it turns out, I ended up have

to trim a bit off the bottom tab that curves around the bottom of the

cylinder to provide clearance for the oil line.

Another thing to point out (arrow in the picture), is the doubler

plate I created for the attachment bolt hole. All the other

attachment bolt holes got these plates, so I thought I should also add

one here.

|

|

Here I have fabricated this angle

stiffener for the right side baffles. Something similar will be

done on the left side, but much beefier because it needs to help support

an oil cooler that is mounted on the baffles. |