|

January 23, 2005: (2.0

hrs.) Got out the broom stick and duct tape to roll the

leading edge of the elevators. I find this to be one of the more

difficult tasks of building this plane. The first roll usually

goes well, but then when you roll the second side of the skin, you have

to deal with the side you just rolled being in the way. You really

have to work the skin to get a good fit. |

|

Finally, the edges are rolled and I can

rivet the leading edge together. Yes, those are the silver #40

cleco's... but I drill the holes out to a #30 prior to blind riveting. |

|

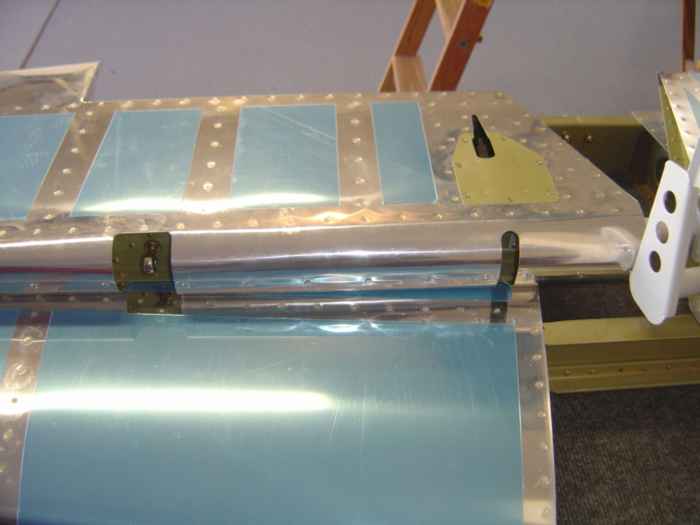

Here is the left elevator laying on top of

the horizontal stabilizer with the leading edge completed.

Next I will need to fit the elevators onto the horizontal stabilizer

and check for proper balance, clearance, and movement. |

|

January 30, 2005: (2.5

hrs.) When the elevators are attached to the horizontal stabilizer,

the outboard skins interfere with the counter balance weight. The

skins need to be trimmed to allow the counter balance to swing freely.

Here I have marked where the top HS skin needs to

be trimmed. This needs to be done on the top and bottom skins for

both the left and right elevator. |

|

This is the final result of the cut after

rounding the corners and deburring the edges. |

|

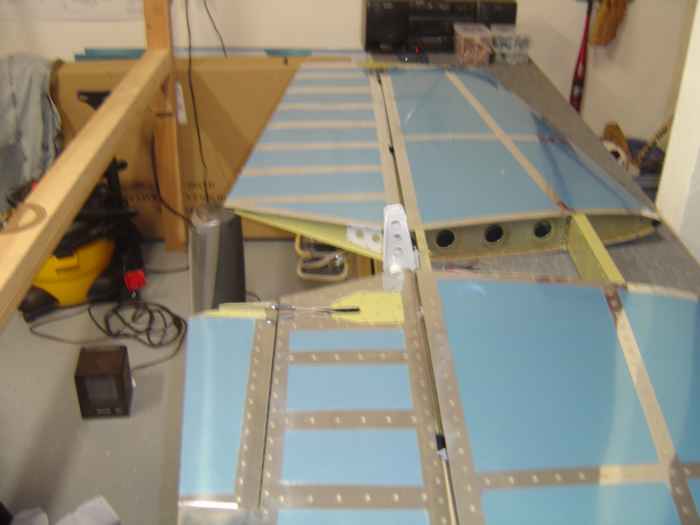

This picture shows the left elevator

attached to the HS. The counter balance weight now has room to

travel freely. |

|

Next I attached the elevators and checked

for movement and balance. Everything fit and moved nicely.

The elevators are balanced a bit heavy, but I will not worry about that

until after paint.

I spend some time today hooking up the linkage of the trim tab servo

to the trim tab. I had to shave away a bit of the trim tab opening

to keep the clevis from rubbing the skin. Next, I tested the trim

tab movement by hooking the servo up to the battery from my rechargeable

drill. It was pretty cool seeing parts moving for the first time.

I am almost done with these elevators. I just need to drill and

bolt the elevators through the center bearing. Hopefully I can get

that done tomorrow and then I can start concentrating on the wings |

|

January 31, 2005: (1.5

hrs.) Tonight I was resolved to finish up the empennage because I

am anxious to start on my wings.

To allow adequate down elevator throw, the rear

spar flange needs to be trimmed. Here you can see that I have marked

where I want to cut. You need to be careful not to cut the rear

spar reinforcements. |

|

I tackled the this job by first drilling

holes in the corners of the area to be removed. This facilitates

the radiused inside edge of the finished cut. Next I used my die

grinder with a cut-off wheel to "carefully" cut through the spar flange.

The spar reinforcements are just beneath the flange so you need to

cut very slowly and make sure to not cut too deep. It would have

been nice if the plans and instructions called for this cut-out before

the horizontal stabilizer was assembled. Oh well, the cut was

fairly easy. |

|

Here is the finished product. Not a

nick on the rear spar reinforcement plate or center bearing support. |

|

The elevator control horns need to be

drilled to accept the bolt that attaches them the center bearing.

The instructions call for using a drill bushing with a 1/4" OD and 3/32"

ID to be used on a #40 drill bit that is then inserted through the

center bearing to drill each control horn. I had this wall anchor

that was close to both dimensions. I wrapped a little electrical

tape on the outside to snug up its fit in the center bearing and then

opted for using a #30 drill bit. This worked out well. |

|

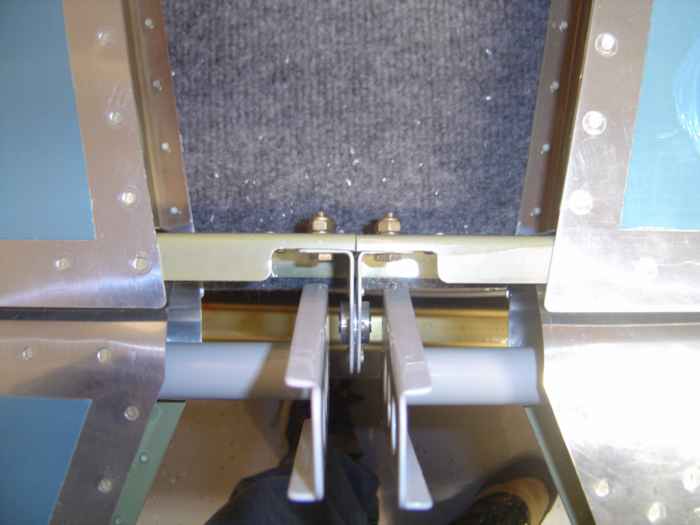

Here the drill bushing is inserted into

the center bearing and I am drilling the right control horn with the #30

drill bit. The same process is used from the opposite side to

drill the left control horn. |

|

The hole then needs to be enlarged to

accommodate the bolt (I believe it was a 1/4" diameter hole). The

bottom hole is what was drilled. |

|

Elevator complete! Now on to the

wings. |