|

January 14, 2005: (2.0

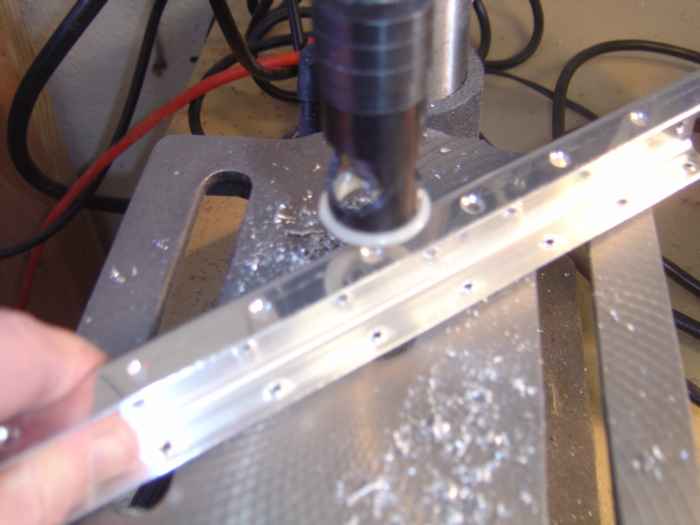

hrs.) Had a bunch of deburring and dimpling to get done on

both the left and right elevator skeletons. Here I am

countersinking the hole in the upper side of the E606PP Trim Tab spar so

that it can accept the dimples in the left elevator skin and trim tab

hinge. |

|

More dimpling... Here I am using the

vise grip dimpler to get into the narrow portion of a rib. |

|

Had to use the blind riveter and a dimple

set to dimple the outward holes in the left elevator skin that mate with

the trim tab spar. |

|

January 15, 2005: (5.0

hrs.) Time to prep and paint all the parts! I like

this part because I know I am real close to putting the pieces back

together for the last time. |

|

Here I am in my protective gear.

Safety glasses, mask, and grungy clothes. I don't want any of the

chemicals getting on my skin. |

|

All the parts are cleaned, etched,

alodined, and then laid up prior to painting. |

|

Painting is complete.

This is the right elevator skin and skeleton parts. |

|

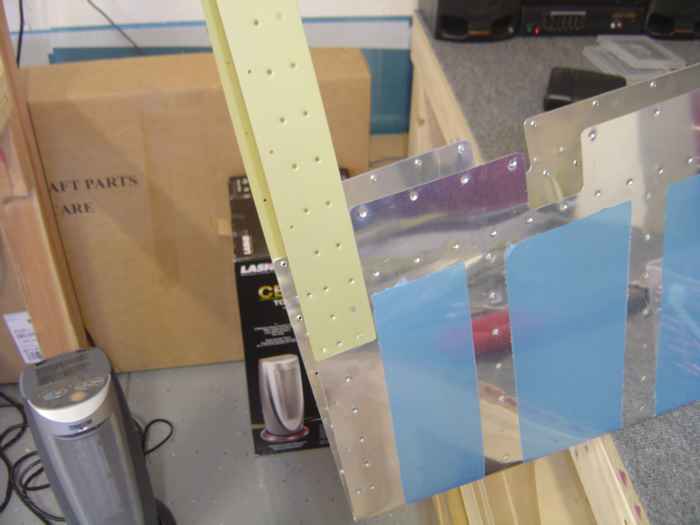

Here is the left elevator skin and

skeleton. Note that the left has more parts. This is because

the left elevator needs to house the trim tab. |

|

Time to rivet. I had to use the

rivet gun to set the rivets in the end ribs. My hand squeezer did

not have a wide enough yoke to for this job. The rest of the

elevator was all hand squeezed. |

|

Here is a close up. Notice I clamp

the piece to the work surface while I rivet. If the piece is not

secured, it may move around and the rivet gun set could slip, damaging

the rivet or the the ribs. |

|

There are two rivets that attach each side

of the counterweight skin to the elevator skin. If you rivet them

now, before the skeleton is inserted, flush rivets can be used instead

of blind rivets. Here the counterweight skin has been attached. |

|

Vans recommends placing a blob of RTV

between the stiffeners on the trailing edge of the elevators prior to

riveting them closed. RTV is a gasket compound use by the auto

industry. I believe the logic is that the RTV will help reduce

vibrations that could lead to cracking on the the trailing edge.

I picked up this tube of Blue RTV from Napa Auto Parts. |

|

Here you can see me applying the RTV

inside the elevator. |

|

Once the RTV is applied, the skeleton is

inserted and cleco'd into place. Next step is to squeeze the flush

head rivets to close the right elevator. |

|

This is the left elevator skeleton.

Before I can insert it into the skin, I need to bend a few tabs on the

skin to close out the trim tab outward edge. That will require me

to build a wood jig to hold the skin in place at the right angle.

I will tackle that job tomorrow. |