|

January 3, 2005: (5.5

hrs.) Back to the project after being out of town for the holidays.

I began the day by prepping the elevator stiffeners for paint.

Here they have been scrubbed in Alumiprep, rinsed and hung to dry. |

|

Once the stiffeners were dry, I then put

batches of them in an Alodine bath for about 2 minutes. |

|

After a good rinsing, the stiffeners were

once again hung to dry. My wing jig sure is coming in handy for

hanging parts :) |

|

While the stiffeners were drying, I got

the paint ready. It is important that the catalyst is mixed well

prior to adding the hardner. I use a mixer in my cordless drill to

for this. |

|

Here the painted parts are drying under a

halogen light. The heat from light makes for a quick drying

process. |

|

After drying for a couple of hours it was

time to back rivet the stiffeners to the elevator skins. Here a

stiffener has been laid across the rivets. |

|

This is my rivet gun with back-riveting

set. |

|

All the stiffeners riveted into place.

This is the right elevator. I also did the left elevator at the

same time. |

|

The trailing edge of the elevators come

pre-bent, but not bent into final position. This is to allow for

access for riveting. Once all the stiffeners are riveted into

place, the leading edge needs to be bent to its final angle. To do

this, I fabricated a bending brake according to the plans. It is a

2'x8' cut into two pieces (44" and 52") held together with five door

hinges. |

|

It is difficult to tell from this picture,

but this is the right elevator in the bending break. To account

for the 1/4" gap created by the hinges, I had to place a piece of 1/4"

wafer board on one side of the elevator during the bend. The

result was a consistent bend and straight trailing edge. |

|

Next, I began constructing the skeleton

for both the left and right elevators. Both elevators involve

basically the same construction with the exception of the trip tab on

the left elevator so it made sense to work on them together. Here is a

shot of the right outboard ribs, counter-balance weight and skin..

The two forward holes are pilot holes that need to be drilled out to a

#12 (all the way through the lead weight). |

|

It is important to use a lubricant while

drilling through the counter-balance weight. Without lubricant,

the lead cuttings from the counter weight will plug up your drill bit

and potentially damage the counter-balance skin or the weight. I

used Boelube with great success. |

|

Next I attached the skins to the skeletons

in preparation for final drilling. In this picture you can see

white powder coated control horn cleco'd to the right elevator. |

|

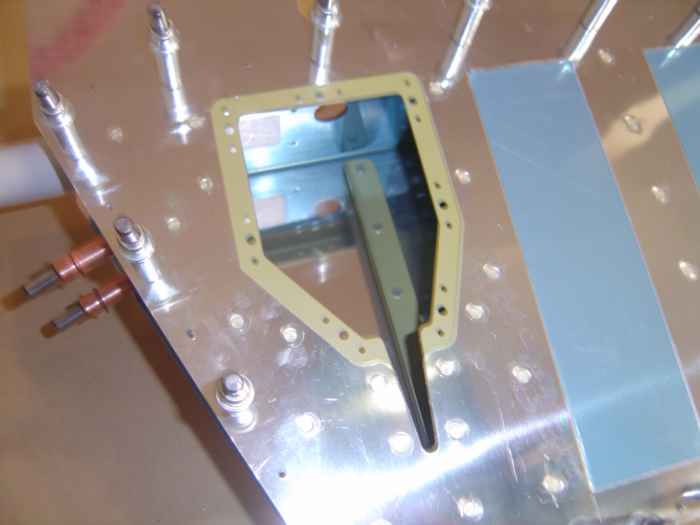

This is a picture of the access cover hole

for the electric trim tab servo on the left elevator. Inside the

hole you can see the stiffener attached to the opposite skin. I

have some concerns that this stiffener may interfere with the electric

servo. I plan to attach the servo to the access cover and test fit

this component before I rivet the left elevator closed. If I

detect any interference in the assembly, I will drill out the rivets in

the stiffener and then re-attach the stiffener with its flange facing in

the opposite direction. |