|

March 7 -

9, 2008:

(10.0 hrs.)

I received the LED annunciators from SteinAir today, so those went

straight into the panel.

|

|

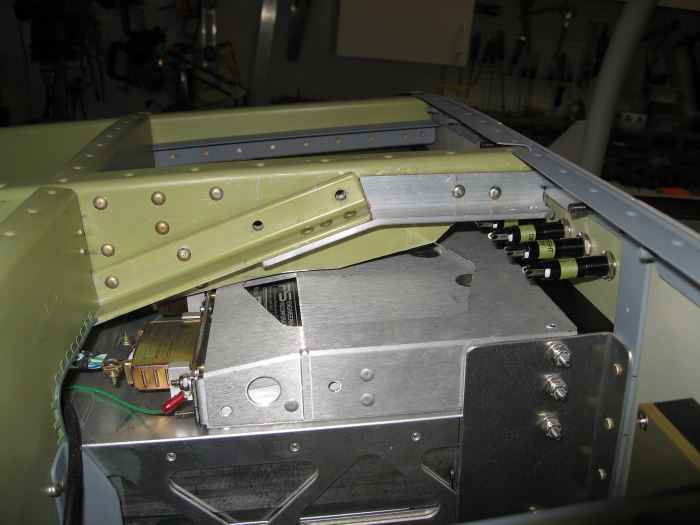

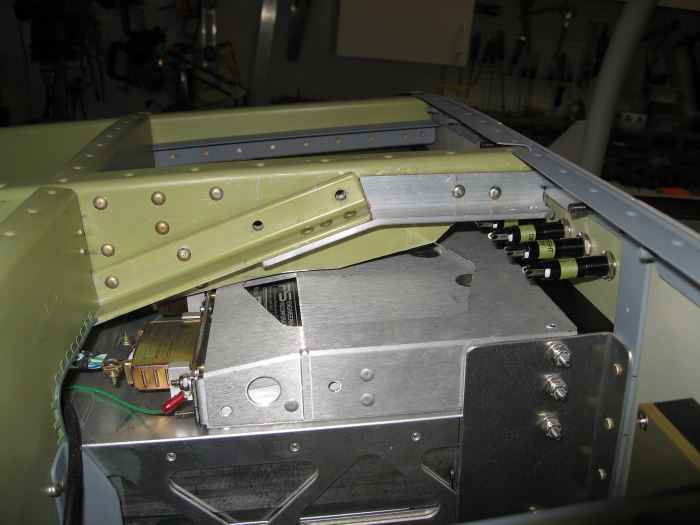

I had to trim the center sub-panel rib

slightly more. I then fabricated a stiffener for this rib out of

some angle aluminum and riveted to the rib and existing stiffener.

This entire setup gets bolted to a vertically rising bar that attaches to

the roll-bar. This will be nice and solid.

I also ran some wires to the low voltage warning annunciators and

tested that they worked. |

|

I installed the CO detector and ELT remote

switch into the panel. I went ahead and wired the ELT switch up.

It only required me to crimp on a telephone style plug to the wires.

I will wire the CO monitor later. |

|

A nice shot of the panel all powered up.

No smoke! |

|

March

14 - April 6, 2008:

(10.0 hrs.)

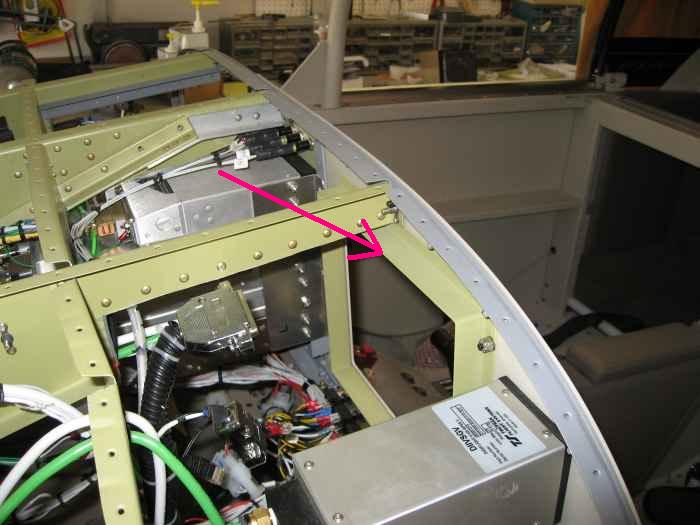

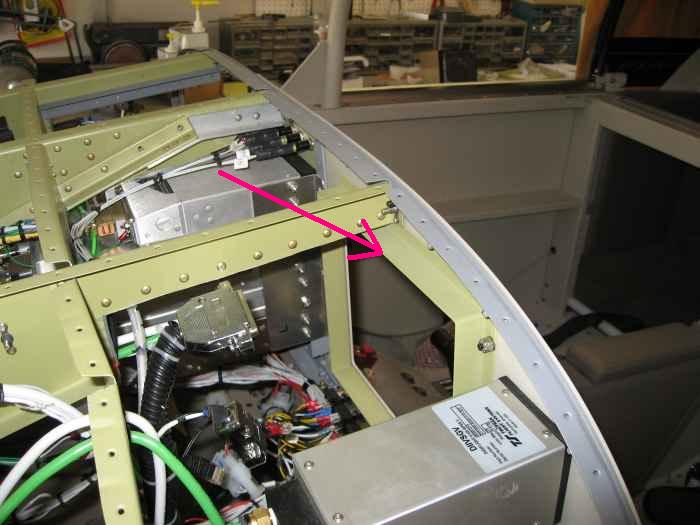

Did some miscellaneous wiring on the panel. Here I wired up my

starter enable switch. The purpose of this keyed switch is to

enable the starter button on the sticks. This is purely a safety

feature. I don't want someone (or me) accidentally hitting the

start button and swinging the prop.

|

|

Here is a shot of the keyed starter enable

switch. It simply open and closes the start circuit on the starter

relay.

Another thing I did, but did not take a picture of was the wiring for

the CO Detector. It required me to solder a couple wires to a DB9

connector and run them to power and ground. |

|

I swapped out some switches on the panel.

Specifically, I changed out the top pair of switches from 2-way locking

toggles to 3-way locking toggles. The initial set of switches

powered up the FADEC A and B busses, with the new setup, they both

provide power to the busses, but also 'enable' the FADEC A and B

systems. So they provide OFF-ON-ENABLE functionality. I

still need to change the label on the panel to reflect this 3-way

action. The lower set of toggles are 3-way switches for controlling

the main and auxiliary batteries and alternators. These were

standard toggles that I changed to the locking toggles. I don't

want to accidentally turn the power off to an electrically dependant

airplane. |

|

April 18 - 20, 2008:

Here are the 3 remote mounted dimmer controls installed in the panel.

Go here for the details... |

|

c , after spending about 2 weeks trying to trouble shoot why my AFS

3500 would not display the engine data from the FADEC serial bus

controller, I finally determined that my AFS unit had a bad serial port.

Today was a sad day, as I had to pull the co-pilot AFS unit out of

the panel and ship it to AFS for repairs.

|

|

Ever since I got my AFS 3500's installed,

I have been wanting to upgrade to the 4500's to get the brighter screen

and faster processor. The unit's will not be available until the

end of the year, but since I had one of the AFS units pulled out of the

panel for repair, it seemed like this might be a good time to prepare

for the upgrade.. The harness is supposed to be plug and play, but

the panel cut out size is different. This means I need to re-cut

the panel opening! Not fun. I do not like taking stuff apart that

I spent a lot of time putting together. Pilot and co-pilot panel

sections are removed. |

|

I enlarged the opening for the two AFS

units and then re-painted the panels. The portions of the panel

that had been labeled were covered with tape to preserve the lettering.

The new paint seemed to match up well with the old paint.

Here the panels are drying. |

|

Re-installing the panels and all the

equipment. One nice thing about the AFS 4500 units, is that they

use a tray system to mount in the panel. This allows the unit to

slide in and out from the front. Nice!

Here is the pilot side AFS tray installed. |

|

Another view of the tray from the front. |

|

Here is the panel put back together...

almost. Still waiting form my co-pilot AFS 3500 to get back from

repairs.

Probably a little hard to see in this picture, but the co-pilot AFS

3500 fits into the larger 4500 tray system using special 'frame' adapter

from AFS. |

|

November 1 - 9, 2008:

(8.0 hrs.)

After riveting the top skin on (not pictures)... this was not too

bad. Most of it could be done from the outside by just keeping the

skin peeled back. The fact that my friend Dan came over to help,

made things move rather quickly. The hardest part were the rivets

that required me to lay on my back in the foot-well and buck rivets

along the longerons. Very painful, but doable. I did use

blind rivets where the top skin meets the panel. I had too much

stuff in there to work around with a bucking bar. Plus, these

rivets will never be seen since I will be covering the glare shield...

Speaking of which, here is my glare shield all upholstered. I

bought the padded edge pre-made from Classic Aero and then ordered some

extra material to upholster the the rest of the glare shield to match.

I think it turned out pretty nice!

|

|

Here is another shot.

One other thing to point out is that I pained the roll-bar black to

match the paint I used on the inside of the canopy. |

|

|

|