|

August 4, 2005:

(3.0 hrs.) Removed the blue plastic from the rivet lines on

both ailerons and then used the C-Frame to dimple the rivet holes. |

|

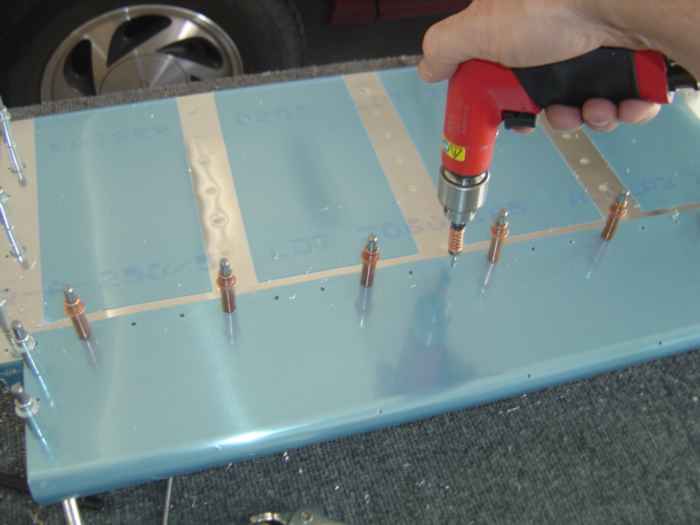

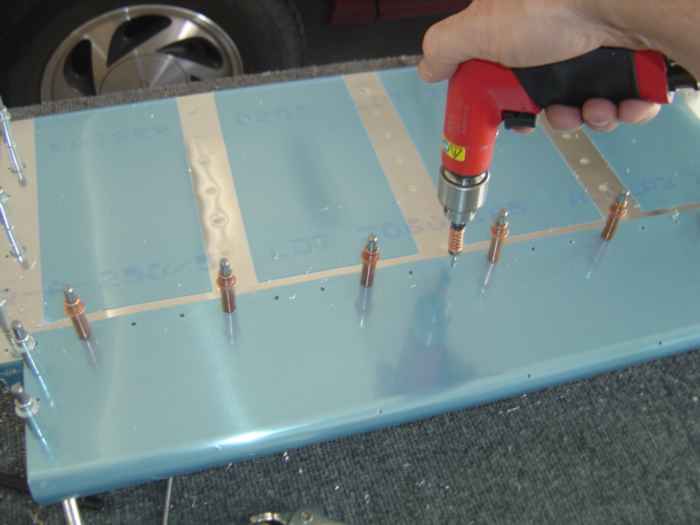

Back riveted each stiffener to both the

top and bottom of the aileron skins. |

|

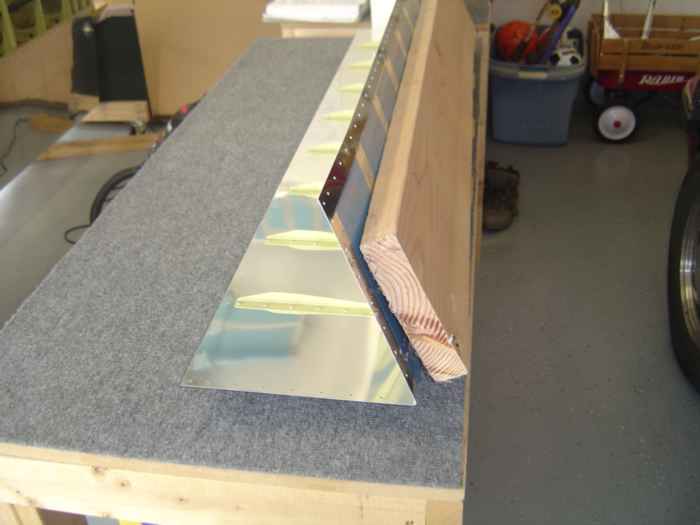

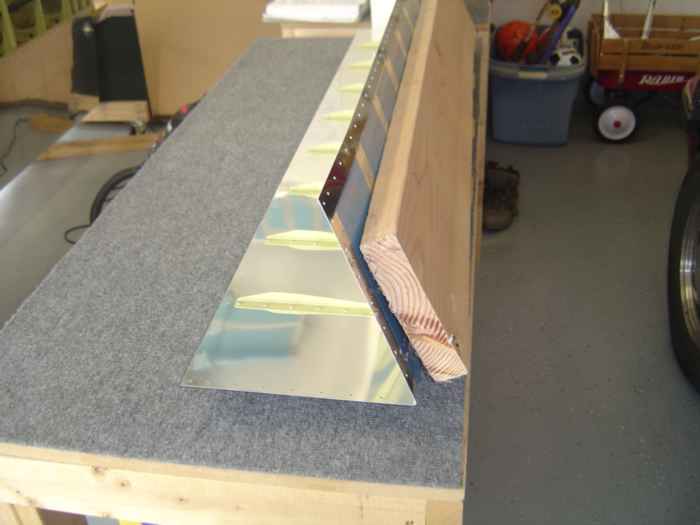

Pulled out the home made brake used on the

empennage and bent the ailerons to the proper angle. |

|

Match drilling the hinge bracket

reinforcement plates to the aileron spars. |

|

Match drilled the aileron leading edge

skin to the trailing edge skin and spar. The aileron end ribs are

also match drilled at this time. |

|

The leading edge to trailing edge joint on

the bottom of the aileron get drilled out to a #30. This portion

of the aileron will be the last section that gets closed so larger blind

rivets will be required.

Not shown: Match drilled the aileron counter weight to the leading

edge skin.

Both ailerons were then disassembled. Next step will be to

debur, dimple, countersink, prep, paint all the parts. |

|

August 5, 2005:

(3.0 hrs.) Deburred all the matched drilled rivet holes

Here I am using the speed deburring bit on the

aileron end rib. |

|

Deburred all the edges of the spars,

skins, and end ribs. Here I am using a Scotchbrite wheel in my

drill press to debur the lightening holes in the aileron spar.

This really makes things move fast. |

|

Next came dimpling of the spars, end ribs,

and skins. |

|

The rivet holes in the counterbalance

weight get countersunk. I used the micro-stop cutter in my drill

press for this job. |

|

Dimpling the rivet to counter balance

holes in the leading edge requires a special technique. There bend

in the skin does not allow the placement of the c-frame dimpler without

denting the skins. I cleco'd the skins the countersunk

counterbalance weight and then hammered a dimple die on the leading edge

rivet holes. I had to prop the leading edge up on some 2x4s to get

the skins off the work table. |