|

|

October 29, 2004:

(1 hrs.) Did some edge cleanup work on the rear VS spar stiffner.

I used a file to take down all the edges then I used a small Scothbrite

wheel on my die grinder to smooth the file marks out. I noticed

that using my die grinder tends to keep my compressor running, which in

turn really heats up the sound proofing cabinet. I think I am

going to have to soon install a ventilation fan to keep the enclosure

cooler. I finished up the evening hand dimpling all the spars and

ribs. |

|

October 31, 2004:

(2 hrs.) Finished up some edge deburring on the front and rear

VS spars. I picked up a wheel from Sears that is made out of that

red Scotchbrite hand pad material. I just chuck it up in my drill

press or die grinder and use it to finish smooth all the edges.

This really works well and is a great time saver. It is especially

useful for taking off of the Alcad coating on the spars prior to my prep

and Alodine process.

Next I prepped and primed all the skeletal parts.

Priming went much better this time. Evidently I did not have the

catalyst mixed well enough when I primed my horizontal stabilizer.

This led to an inconstancy in the paint and its adhesion. This

time painting was a piece of cake and the pieces came out perfect.

I cleco'ed together the

front and rear VS spars and preparation for riveting. |

|

November 1, 2004:

(2 hrs.) Riveted the ribs to the VS front spar |

|

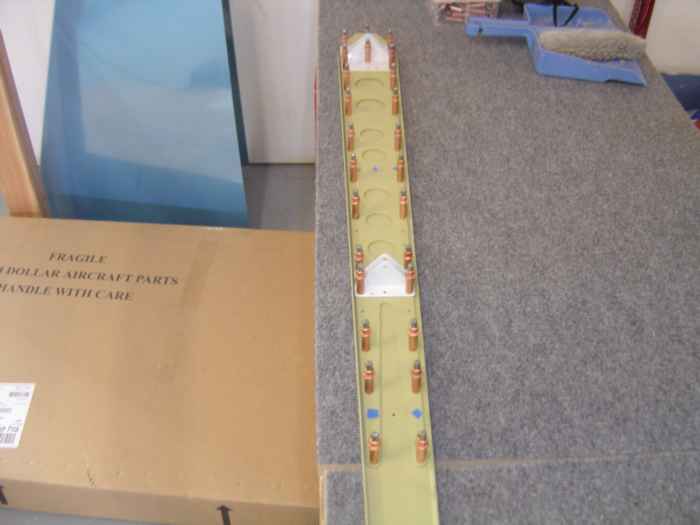

Here is the VS rear

spar completely riveted. |

|

Removed the plastic

from the rivet lines on the VS skin. Tomorrow I will deburr and

dimple the skin |

|

|

November 5, 2004:

(0.5 hrs.): Deburred and dimpled the VS skin. Hopefully tomorrow I

will rivet the skin on. |

|

November 6, 2004:

(2 hrs.): I was not able to find an extra set of hands to help with

riveting so I proceeded to buck and rivet myself. There was

plenty of room to get one arm in the VS to hold the bucking bar while I

held the rivet gun in my other hand.

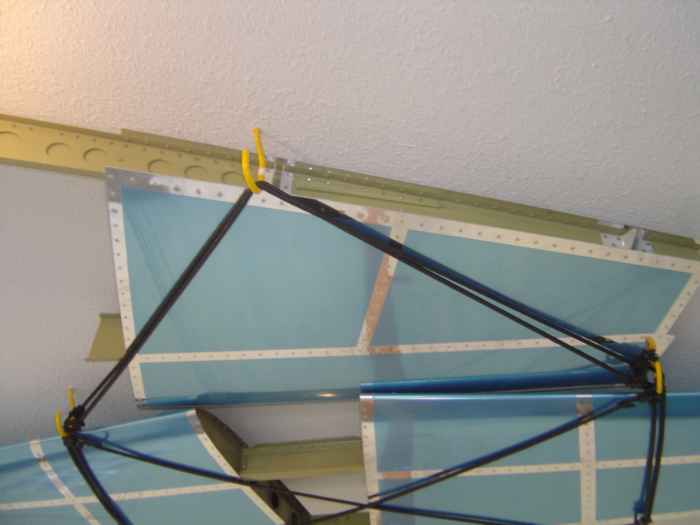

Here is a picture of the VS with the rear spar

removed to provide access for riveting. You can see there is

plenty of room to get an arm in there. |

|

The is the VS with all

the rivets completed in the forward spar and center rib. The rear

spar has been cleco'd into place for riveting with the hand squeezer. |

|

The completed VS

hanging from the ceiling next to the HS. |